All blog posts

Six Security Standards That Equipment Manufacturing Companies Need to Know About in 2026

We outline the four most important EU security standards: EU Data Act, Cyber Resilience Act, NIS-2, IEC 62443, RED and EU Machinery Regulation and show you how they strengthen cybersecurity.

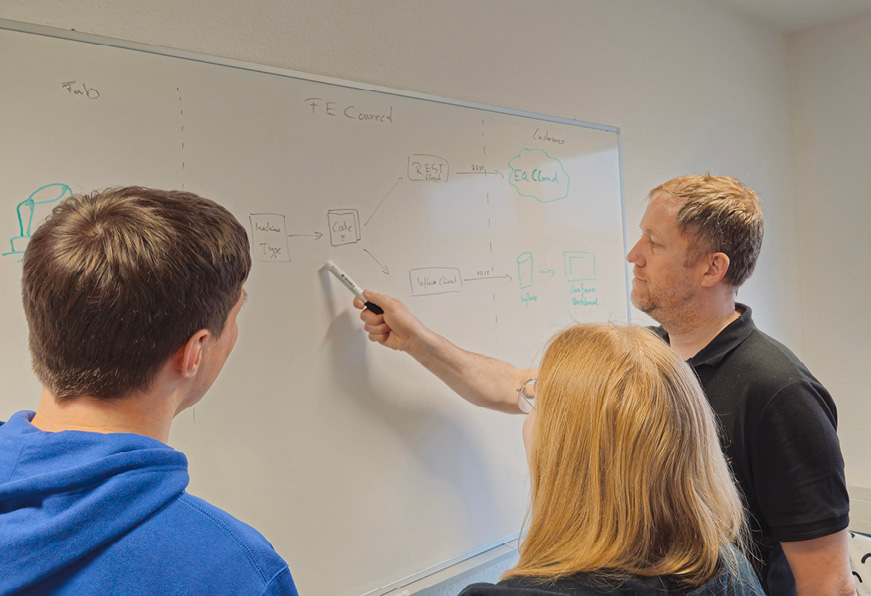

Cybersecurity in Factory Automation: Why Software Vendors and Manufacturers Must Act Together

Connected production environments increasingly rely on secure software to maintain high availability. We explain how manufacturers should handle NIS-2, the Cyber Resilience Act (CRA), and DIN EN IEC 62443, which risks can arise in OT systems, and how we embed cybersecurity into our software solutions for factory automation from the start.

Digitalization in Equipment Manufacturing: What We Learned at the Meet Up at PVA TePla

What happens when equipment manufacturers, service teams and digitalization experts talk openly about their experiences? The meet up “Equipment Manufacturing Goes Digital” showed what becomes possible when real insights, honest feedback and shared learning take center stage.

SECS/GEM Integration Beyond Semiconductor Factories: How a Proven Standard is Gaining Ground in New Industries

SECS/GEM leaves the semiconductor floor: Why the standard matters for sensor and electronics manufacturers and how the low-code integration software FabEagle®Connect bridges the gap to traditional systems like MES, ERP, and Cloud.

More than Just a Job: Thomas Dreyer About Leadership and Science Fiction – Part 2 of the Interview

What inspires an R&D team leader at Kontron AIS? In this interview, Thomas talks about science fiction, leadership, programming, and his motto in life. The entire conversation is also available as a video directly below the text.

From Boring to Branded: Align Your Customer Portal with Your Corporate Design in Equipment Manufacturing

A Customer Portal That Fits Your Brand? With EquipmentCloud®, you can customize the design, colors, and style to create a seamless user experience that brings your brand to life in digital service—and sets you apart from the competition.

25 Years, over 40 Team Members, Countless Projects – And Not a Bit Tired

For 25 years, Thomas has been shaping the software world at Kontron AIS. In the first part of the interview, he shares insights into technological milestones, international projects, and his enthusiasm for smart ideas – read now and watch the video!

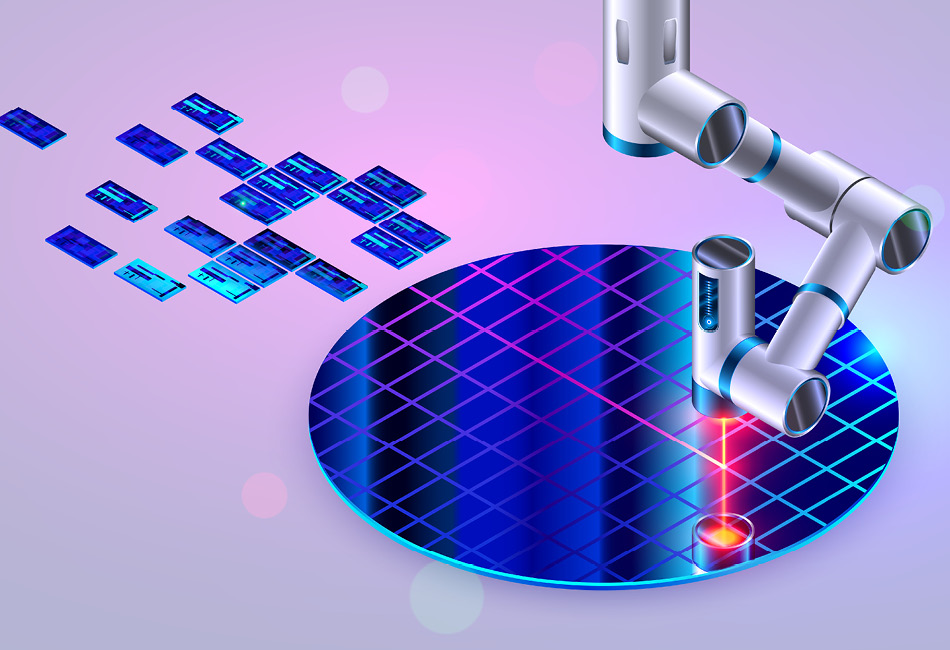

From Act to Opportunity: How the Cyber Resilience Act (Cra) Reinforces Cybersecurity in the Semiconductor Industry

The Cyber Resilience Act (CRA) sets new cybersecurity standards and challenges the semiconductor industry, as well as many other industries. What obligations do companies have, what deadlines apply, and how can the new standards be implemented? We provide an overview and demonstrate how our software solutions are already well prepared.

Systematic connectivity: Why expertise is indispensable for integration projects

Standards and low-code are common in connectivity, but every integration project has its specific challenges. Find out why expertise is the key to successful projects and how Kontron AIS can help you.

Making semiconductor equipment fit for the future with retrofits

Long-standing equipment are an economic advantage, but new trends and technical requirements put their performance to the test. Retrofit solutions enable the future-proofing of existing equipment with modern interfaces, intuitive control systems and advanced hardware components.

Reach Goals Faster with Customer Success Management in the Digitalization of Equipment Manufacturing

Customer Success Management is the key to making optimal use of EquipmentCloud®. Find out how we ensure your success with application-specific support, close partnerships and innovative strategies while perfectly customizing the development of our solution to your needs.

From Retrofit to Cybersecurity: Kontron AIS at Semicon Europa 2024

SEMICON Europa 2024 is the meeting place for the semiconductor industry. With exciting presentations, our innovative solutions and a special award for our team, the traide fair was a complete success. Find out what trends are driving the industry.

Why Single Sign-on (SSO) and Multi-Factor Authentication (MFA) Are Indispensable for Modern Customer Portals in Equipment Manufacturing

Customer portals in the mechanical engineering industry manage sensitive data and need to be both user-friendly and secure. Technologies such as Single Sign-On (SSO) and Multi-Factor Authentication (MFA) offer a solution: they increase security, minimise risks and ensure a convenient user experience.

Databases in production IT: Which database is the right one?

Databases are the backbone of modern manufacturing IT for managing and analyzing large volumes of data. Find out which types of database there are, which advantages and disadvantages they have, and how to find the right solution to optimize your production processes.

Drivers of digitalization: an interview with our product management

In our interview, discover how our product managers are shaping the future of our industrial software products with passion and strategy, meeting customer requirements and driving forward innovations.

HTEL Manufacturing to Produce Gigawatts of Energy from Green Hydrogen

Green hydrogen is key to the energy revolution. The H2Giga project sees us support the manufacturing of high-temperature electrolyzers (HTEL modules) with modern IT infrastructure. Find out how this helps us contribute to sustainable hydrogen production.

KPIs in manufacturing: Your guide to pptimization and increasing efficiency

This is how you can also optimize your manufacturing with production statistics and key performance indicators (KPIs): We provide you with an overview of the differences and advantages. You'll also learn everything about the top 3 key performance indicators and the best tools.

Efficient and Flexible: How an Open Software Framework Gets You Equipment Control Faster

Programming your own equipment control can be time-consuming, require unavailable resources and up in incomprehensible complexity. A solution must be found. An open-programming framework saves time, provides regular cyber security updates and enables flexible, modular solutions for specific machine requirements.

My Visit to the IoT Solutions World Congress & Barcelona Cybersecurity Congress 2024

Every year, the IoT Solutions World Congress 2024 in Barcelona showcases the latest developments in IoT and cybersecurity. From the latest AI and ML trends to regulatory challenges, this report provides a comprehensive overview of the key themes and highlights of the show.

Innovation Is Driven by Sharing Ideas: This Was Our 23rd User Conference 2024

At the 23rd User Conference 2024, nearly 150 experts from various industries gathered to hear exciting presentations on "More than just software development – behind the scenes of code generation".

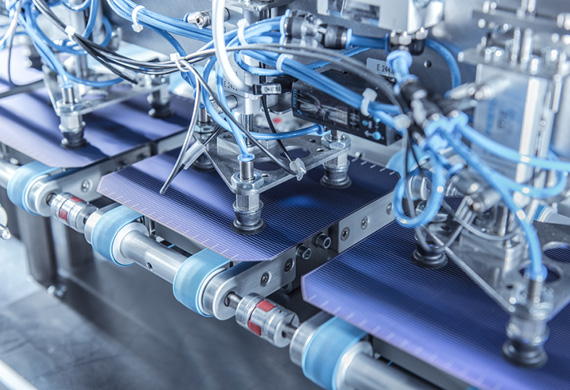

How single wafer tracking optimizes solar cell production

Single wafer tracking helps optimize the efficiency and quality of solar cells. Find out how the precise tracking of individual wafers is revolutionizing photovoltaic production and why this lowers costs and shortens ramp-up times.

From the Edge to the Cloud: New Potential for Component and Device Manufacturers as Well as Equipment Manufacturers

Edge devices are transforming industrial automation by not only processing data efficiently, but also providing critical insights for process optimization. Integrating security and connectivity with fleet management and digital services enables highly scalable and secure systems.

Pilot projects – Make sure you avoid these pitfalls when digitalizing your production

You don’t necessarily need a think-big approach to start production digitalization. We'll show you why it's worth taking a look at pilot projects, which five pitfalls to avoid and what the ideal preparation looks like.

Multilingual Customer Portal: The New Translation Functionality Offers Communication without Borders to Improve Cooperation

The new translation functionality of EquipmentCloud® enables mechanical engineering companies to offer a new level of customer service: The multilingual customer portal ensures communication without borders worldwide. An innovation that strengthens the bond between mechanical engineering companies and operators and crosses cultural borders.

Sustainability as a Corporate Culture: Our Path to a Greener Future

As a company with over 250 employees, we see it as our responsibility to take a critical look at our ecological footprint. In addition to the environment, we also focus on social and economic factors in terms of sustainability.

A Crystal-Clear Future: How Equipmentcloud® Is Revolutionizing the Production of Wafers and Crystals

Take a look into a crystal-clear future where industrial manufacturing processes are seamlessly linked to the latest information and communication technologies. The “Wafer 4.0” project has revolutionized crystal and wafer manufacturing, opening up a new era of efficiency.

Shaping the future: How low code is sustainably redefining and changing connectivity

Low code is a connectivity game changer that is here to stay because it enables highly efficient workflows for interface integration. Discover the advantages that low code offers for driving the digitalization of your production.

Solar Trends in Silicon Valley: My Trip to PV Cell Tech 2023

PV Celltech is the hotspot for PV experts in the USA. The conference in San Francisco offers insights into the latest developments and challenges in the solar industry. Our Senior Sales Manager for Manufacturing Execution Systems, Frank Tannhäuser, was there once again this year and reports on his experiences.

Opportunities and challenges in the digitalization of production control for medical products and pharmaceuticals

Manufacturers of medical products and pharmaceuticals face major regulatory challenges in the digitalization of their production. Read our interview to find out exactly what these are and how GMP-compliant production control in particular can help.

David or Goliath? What is the difference between the introduction of a line controller and a factory-wide MES?

MES or line controller? This is a question many production managers ask when digitalizing their manufacturing processes. We will explain the differences in launching both production control systems in terms of duration, tasks and costs.

Connectivity in the World of IIoT

Fully networked manufacturing requires interface connectivity between heterogeneous systems. Software for interface integration provides an advantage here in achieving the goal of a reliable, secure and flexible connection.

Coating Technology 2.0: How Software is Revolutionizing the Production of Photonic Components

The joint project 3D-FF explored ways to improve magnetron sputtering technology to enable high-precision coating systems for photonic components — and the software know-how of Kontron AIS was also called upon.

How Data Analysis at Process Level Boosts Service Success in Equipment Manufacturing

Machine manufacturers benefit from the in-depth analysis of process values through regional comparisons, proactive service and insights for product development.

Cloud-based production control system: An insight into the Kontron AIS AllMeSa funding project

Together with ten partners, Kontron AIS GmbH is participating in the AllMeSa research project funded by the Federal Ministry of Education and Research (BMFB).

No Two OEE’s Are the Same! How Machines Can Be Evaluated Across Industries

Overall Equipment Effectiveness, better known as OEE, is the gold standard for measuring productivity in manufacturing. Read here how machines can be evaluated across the board.

How to Maximize the Efficiency of Your Site Acceptance Tests During Commissioning

Learn how to improve the efficiency of Site Acceptance Tests (SATs) for smooth commissioning and discover best practices for streamlining the entire process.

Product insight: How to increase productivity and customer satisfaction with machine monitoring

Visualize, analyze and anticipate: This portfolio review sheds light on the importance of machine monitoring from various standpoints.

Device Management: A Must-Have for IT Managers in Equipment Manufacturing

Management and monitoring of IoT devices in the field: The must-have for IT managers in mechanical engineering. From central onboarding to management and monitoring — all in one tool.

Digital Customer Portal: Benefits for Sales and Service

Sales and service go hand in hand!? This is no longer wishful thinking but is becoming an integral part of standard practice.

Data-Based Maintenance: Intelligently Planned and Implemented With a Focus on Saving Resources

Digitally planning maintenance of machines and systems and using artificial intelligence to calculate service cycles: that is the future of mechanical engineering.

No entries