Ensure your market access to semiconductor, photovoltaic and electronics manufacturing with SECS/GEM, GEM300 and EDA interfaces

In order to secure market access to the semiconductor industry as a equipment manufacturer, compliance with the SECS/GEM, GEM300 and EDA SEMI standards is essential. SECS/GEM interfaces are used as an industry-specific integration layer in the semiconductor industry and for photovoltaic, LED, flat panel and electronics production. With the top level GEM300 SEMI standards (E39, E40, E87, E90, E94 and E116), you address fully automated and modern factories, while EDA is becoming increasingly important as a flexible and powerful interface for providing process data.

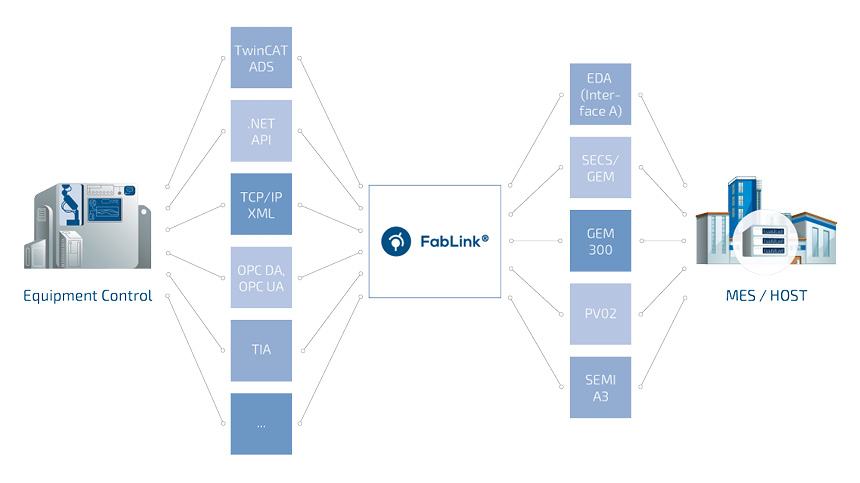

Fablink®: The Easy Way to a SEMI-Compliant Interface for Equipment Integration

FabLink® is the standard-compliant solution for implementing SEMI standards for the vertical equipment integration. With more than 16,000 installations worldwide, it is an advanced and well-established software solution that offers a wide range of connectivity options and supports various standards:

| FabLink® to the equipment, e.g.: | FabLink® to the MES/host: |

|---|---|

|

|

Get help from experienced project teams

We have been supporting and realizing equipment integrations in the semiconductor industry with FabLink® for more than 20 years. This has involved working with SEMI standards on a daily basis, and as a result we are your reliable partner for training, requirements analysis, consulting and project support. In addition, we develop possible solutions together with you and your customers. Thanks to continuous product development and the provision of updates, we ensure your compliance with SEMI standards, even as they continue to evolve.

Profit from a high level of planning security and predictable costs

FabLink® gives you planning security, especially during initial projects. In contrast to software developed by companies in-house, where costs can become unmanageable, especially if you do not have much industry experience, with FabLink® you benefit from calculability through binding offers for project implementation and clear licensing structures without recurring annual payments. This ensures that you stay within your implementation budget.

Enjoy low costs in follow-up projects

Configuring instead of programming – with FabLink®, you can already configure subsequent projects independently if desired and carry out commissioning on your own, thanks to the training provided as part of the initial project. All that is needed are the runtime licenses for the individual machines.

Fabeagle®Connect: Low-Code Integration Software for SECS/GEM Host Interface

Even outside the semiconductor industry, the established SECS/GEM standard is increasingly being used to efficiently integrate machines with semiconductor-like manufacturing processes into production control systems such as MES, ERP or databases. With our low-code interface integration software FabEagle®Connect, you can seamlessly connect machines via a SECS/GEM host interface.

Your Contact Persons