Process-Oriented Production Control, Management and Data Acquisition for Your Production Lines

Modern and adaptable solutions for production control on automotive and electronics assembly lines are required to keep pace with their increasing complexity and flexibility. Comparable to an MES (Manufacturing Execution System), line controllers offer all the function modules needed for data acquisition, process control and visualization. They deliver impressive MES functionality for individual lines, high scalability, significantly lower implementation costs as well as short project runtimes.

Challenges in Modern Production Control for Automotive and Electronics Assembly Lines

Today's production and manufacturing lines face a wide range of challenges that require modern production control.

- Shorter cycle time: New products and production processes are driving higher customer demands like cycle time optimization.

- Quality control and verification: Increasing quality requirements for products and process accuracy must be constantly tested and documented.

- Resource optimization: Sustainability and cost optimization require the best possible utilization of machines and materials.

- Scalability challenges: A fast-moving sales market requires demand-driven production with a high number of variants.

- More complex data interfaces: Modern production control requires the connection of OT, IT and logistics with a large number of complex interfaces.

Factory operators and machine manufacturer who are willing to adapt and invest in optimizing their production and manufacturing processes overcome these challenges and gain a competitive advantage.

FabEagle®LC – The Solution for a Wide Range of Applications

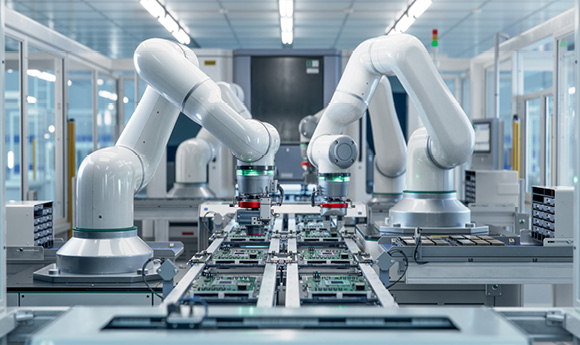

FabEagle®LC line controller: The solution for assembling electronic devices

The FabEagle®LC line controller enables the effective management and control of complex assembly processes. It offers real-time process monitoring, allowing the manufacturing processes of every component on the assembly line to be tracked. This ensures that product-specific process parameters are met and that the assembly sequence is error-free. To enable a quick and reliable switch between different product variants, the line controller supports the input of machine parameters and material batches based on recipes and parts lists.

The control of material and product movements along the assembly line enables processes developed specifically for electronics assembly to be implemented, such as combining components from the pre-assembly and final assembly lines, and buffering units within the production line. Thanks to this flexibility of material flow control, you benefit from a smooth assembly process.

The line controller also enables data acquisition for mechanical, optical and acoustic tests, ensuring complete traceability of product quality. Alarms, states and cycle times logged for each of the production machines help to minimize downtimes, avoid bottlenecks and optimize overall production efficiency.

| Applications in electronics assembly: | |

|---|---|

|

|

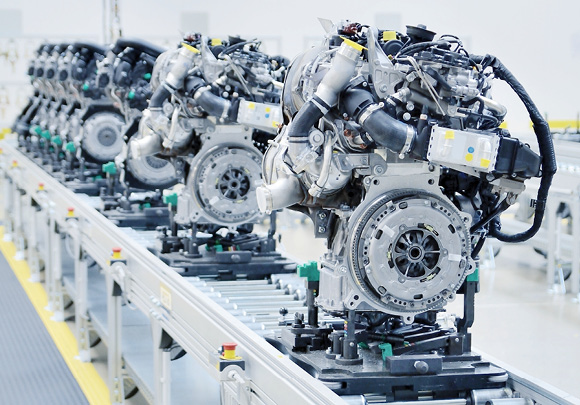

FabEagle®LC line controller: The solution for assembling automotive parts

Maximum cycle rates with a high level of process quality can only be achieved if order processing is supported by digital work schedules, recipes and parts lists. The interaction of these production requirements is enabled by fully automated process control using the FabEagle®LC line controller. As a result, the connected machines and systems become more efficient and achieve the fastest cycle rates, even with a wide range of variants.

Line controllers play a decisive role in quality assurance in the assembly of automotive components by logging batch, process and test data. FabEagle®LC enables fully automated tests that ensure that every product meets the requirements specified in each recipe. Any deviations or errors are immediately detected and appropriate rework processes initiated. This class of automation reduces waste and improves product quality without compromising on the output of the production line.

Data is also archived in parallel with the production processes. In addition to the classic database, line controller archiving compresses complex data to enable efficient data storage over many years. You can use the data archive to prove the quality of your products and carry out additional evaluations at any time.

| Applications in automotive assembly: | ||

|---|---|---|

|

|

|

Your Contact Person