The people who work with us are the driving force behind Kontron AIS. We now have over 250 colleagues who are dedicated to industrial software. Developing our software products is complex. To strategize this complexity, we set up the product management division more than five years ago. That is how we develop and implement a clear and focused product strategy.

Our product managers analyze markets, customer requirements and future trends. They evolve the knowledge gained into new requirements for product features to strengthen our innovative capabilities. By working closely with the management, development, sales and marketing, they ensure that everyone is on the same level and pulling in the same direction.

Today, our products are managed by a strong team of three specialists in product management. In an interview, we invited them to share more about their work, their priorities and their visions. What motivates them? What influence do our customers have? What are the challenges they see? These and other questions will be answered by:

Vanessa Kluge,

our product manager for digitalization

Natalie Schulze,

our product manager for equipment control and integration

Robin Schubert,

our product manager for manufacturing automation

9 Questions for Our Product Managers

- Your passion is product management, so can you briefly explain what fascinates you so much about it?

- Which of your tasks do you like best?

- Speaking of customer feedback, what influence does it have for you and how is it integrated into the development process?

- How have the expectations of our customers changed in recent years?

- How do you manage the balancing act between customer requirements and the technical possibilities or limits of standardized products?

- What are the biggest challenges in product management for industrial software?

- What significance does cybersecurity have for industrial software in general, and for your work in the coming years?

- What trends do you see that could influence our products in the future?

- Last but not least, let's look towards the future: What is your vision for the use of industrial software in equipment manufacturing and by factory operators in 10 years’ time?

1. Your Passion Is Product Management, so Can You Briefly Explain What Fascinates You So Much About It?

Natalie: In product management, the tasks are varied and no day is the same. From market research and customer meetings to product design with a focus on customer benefits and marketing measures, everything falls within the tasks of a product manager. I can't remember a day when I was ever bored.

Robin: As a strategist, I love the challenge of balancing the various requirements of different customers and developing a product strategy that offers the greatest added value to existing customers as well as new customers. I also feel the same way as Natalie: As a link between sales, marketing, product development and project department, I never get bored.

Vanessa: I am so enthusiastic about product management because my work allows me to actively design products and ultimately directly influence the success of the company. The interface function is an absolute asset both on a personal and professional level, because the focus is on solving challenges together and across functions. I also love asking why and getting to the source of problems directly with product users.

2. Which of Your Tasks Do You like Best?

Robin: For me, it is definitely developing product strategies and processing the various requirements of our stakeholders. The central question of what new added value FabEagle® can offer our customers over the medium and long term, and which functions new customers and existing customers use, has many facets that need to be identified and evaluated as objectively as possible. So communication is the main focus: Communication with customers, development, sales, but of course also communication in the form of marketing are the key to good product management.

Natalie: For me too, it is working together closely with development, project implementation, sales and marketing. Each division has varying degrees of technical understanding of our ToolCommander® and FabLink® products. It is often necessary to put forward important arguments, draw attention to product features and subtleties and to filter out exactly what is of interest to the various participants and stakeholders. Also during demo sessions with customers, it is important for me to understand a customer’s issues and immediately offer appropriate solutions.

Vanessa: I think it's all about how we can attract new customers, as well as new market segments for our products and, on the other hand, to continuously inspire our existing customers and help them to achieve sustainable success. That is why I introduced completely new work processes and methods for the two products EquipmentCloud® and KontronGrid and set up different content formats for communication. Over the years, we've assessed a lot of what's been done; we've covered an unbelievable amount of things, tried out, tested, refined, and in the end sometimes thrown them overboard. In particular, we need to keep coming up with answers to new questions such as cybersecurity, cloud security and data protection. What makes my work so varied and exciting is the close interaction with edge hardware and other software from Kontron AG's portfolio that presents us with new challenges in terms of compatibility, shared storytelling for different markets, coordinated pricing strategies and profitability for the entire product portfolio.

3. Speaking of Customer Feedback, What Influence Does It Have for You and How Is It Integrated Into the Development Process?

Natalie: Customer feedback is essential to our work. Our goal is to solve our customers' problems and help them face their challenges. To do this, we also need to read between the lines. Solutions may be quite different from what a particular customer imagined. We also solve challenges that several customers face in a way that as many customers as possible benefit from the solutions. Even before developing new products, we collect customer feedback, continuously adapt existing products, and keep in close contact with our customers, like at our user conference.

Robin: I can only agree with Natalie here. Every customer’s voice counts and is part of a big picture that shapes the development of our products. The key challenge is to identify the source of the customer’s problems from specific inquiries and expectations. There are several solutions for a problem or task, especially in the area of factory automation, that more or less quickly arrive at the goal. In the end, innovation in software development means processing this information, new technologies and our data in such a way that complex relationships can be easily identified, and solutions can be derived.

Vanessa: The same applies to our digital transformation solution, we are in continuous contact with the various users in order to gain a deeper understanding of their issues and challenges. In addition to existing customers, target customers from various industries who are evaluating solutions are another helpful source of feedback, especially to obtain a picture of current problems regardless of whether they are already users. The same applies to acquired and lost customers. There are an incredible number of touchpoints on which to base interviews and get valuable and honest feedback. Our task is to synergize and evaluate the feedback. To do this, we also rely specifically on multipliers from the entire product team: from customer success and support, marketing, to sales and developers, in order to use as many different feedback channels as possible. Ultimately, there are many people working on obtaining a better understanding of the needs of customers.

4. How Have the Expectations of Our Customers Changed in Recent Years?

Natalie: Regarding equipment control and integration solutions, there is a trend towards wanting more flexibility and, as a result, a balanced distribution of tasks. In the past, we have mostly implemented complete projects and integrated software that the customer is already using. Our customers now want to participate in project implementation, whether due to time pressure or to protect internal knowledge. We take these requirements into account. For example, the new ToolCommander® framework enables our customers to flexibly take over parts of the programming of the equipment control themselves or to maintain the system control independently after project completion and integrate smaller features in future by themselves. While these options reduce dependency on external resources, we are still their strong partner for training and consulting.

Vanessa: Our customers' expectations have changed towards achieving a higher level of user-friendliness. The key here is clearly the ease of use, which by the end involves every user group. Interoperability also plays a major role in scaling, either because the digital transformation is to be implemented across departments in order to be able to offer their customers an end-to-end user experience or because maintenance costs need to be reduced and the IT landscape better connected. The requirement is also increasing for intelligent linking of content, simplified search functions and availability of information, including through increased AI support. The reasons for this include the high efficiency requirements, the ongoing high turnover of employees in companies and the associated lack of long-standing expertise in service and after sales.

Robin: If I had to break it down to one word for factory automation, it would be flexibility. Firstly in terms of high availability and adaptability of the user interface, and secondly in terms of expandability, for example for new production machines and processes. That is why we need to look at web front-end technology, offer more configuration dialogs and develop scalable services for the backend. This means that all possible and permitted actions of users must simply be enabled and supported by the software.

5. How Do You Manage the Balancing Act Between Customer Requirements and the Technical Possibilities or Limits of Standardized Products?

Vanessa: We are managing the balancing act better and better, although not always perfectly. But what has helped us particularly well is to shift our product strategy to vision-driven products. What drives us, and which problem shared by the majority of our target group and customers do we actually want to solve? We try to record customer requirements neutrally as customer feedback and to assess them on the basis of two criteria: Do these requirements support the product in terms of our vision? Do they contribute to the successful development of the product in the long term and, as a consequence, benefit the target group? If customer requirements are not met by the standardized product, then our experienced project teams offer the appropriate know-how and flexibility to solve them another way.

Robin: Our FabEagle® software products don't fit into an obvious template that most people think of as standardized products. Although we can use our software solutions directly with customers without further adaptation or expansion, in many cases, our products are also a proven basis for much more complex custom-built solutions that are tailored precisely to match our customers' production processes and challenges. The strong combination of products and diverse project teams has been inspiring many of our existing customers for years, because they enable us to meet specific customer and industry requirements quickly and reliably.

Natalie: In our division, our first customer is inside our own company. As a first step, the new equipment control framework version from product development is delivered to the division that implements customer-specific projects using ToolCommander®. So we always have very direct feedback to help master the balancing act. In addition, there is close contact with our customers in equipment manufacturing. This is where active listening is important again: What do our customers really appreciate? What wish or need lies behind an enquiry? Can we already solve this another way, or can we make several customers happy with a slightly different solution? Customer requests can also be included in the product planning roadmap. But it also works the other way around: Features and functionalities that have not yet been implemented in the product can be integrated in the project realization. This is also in line with the open concept we use to develop our framework and APIs.

6. What Are the Biggest Challenges in Product Management for Industrial Software?

Robin: An important point is certainly the product lifecycle. Our line controller software and integration solutions run for very long periods of time with our customers, which is why we offer regular updates. For us, this means that when we develop our products, we must always keep in mind not only new functions but also requirements in terms of updatability, backward compatibility and security against new threats. When we deliver software to our customers, we guarantee that they can receive updates from us for years to come. Security, reliability, and performance are our biggest priorities

Natalie: Robin is absolutely right. Industrial manufacturing plants have long life cycles. Software, on the other hand, is flexible and fast-moving. Version changes can affect not only operating systems, but also development platforms, for example. In addition, new requirements come in over the years, such as new industry standards and laws like the Cyber Resilience Act. This typically results in shorter release cycles. The biggest challenge is therefore keeping production equipment software up to date and secure for decades.

Vanessa: I also see offering the highest security standards with maximum flexibility as one of the biggest challenges. Although cloud solutions are an integral part of many business processes, we still encounter customers with major reservations in the OT sector. In particular, the question of transparent handling of machine data is always an issue. Our customers in the industrial sector need reliability, sustainability of the solutions used, and focused industry relevance. As a software provider, we must rely on the latest technology and security standards in development, because cybersecurity requirements are becoming increasingly demanding and we can also remove a number of hurdles for our customers here.

7. What Significance Does Cybersecurity Have for Industrial Software in General, and for Your Work in the Coming Years?

Natalie: For us, cybersecurity starts in the concept phase. The development team looks at features and software modules in connection with the overall system and presents its possible solutions for internal discussion at regular meetings. All current requirements are also taken into account. This is how we ensure that we arrive at the best solution. Our software products regularly go through vulnerability checks, and CVEs are tracked and evaluated with the help of SBOM. Our goal is to proactively provide machine manufacturers with information that is already analyzed and evaluated in terms of the security of their software and to coordinate necessary updates with them on a regular basis.

Robin: Cybersecurity starts with the qualitative development of software. Well before the Cyber Resilience Act became a thing, we had already established processes that support code quality, test coverage, and source code management. Over the next few years, we will continue to optimize our update processes for customer projects. Our goal is that every customer who has set themselves the goal of running secure software also receives support and updates from us.

Vanessa: Cybersecurity is also an integral part of development and deployment for us. I agree with Robin here: we have established secure development processes, which we are continuously evolving. Security-by-design and transparency are important strategies for us. Comprehensive documentation and continuous analysis of software components against volatile threats (CVE, CWE) as SBOM, for example, are topics that we think are very important. We also focus on the interplay of secure and compatible hardware and software components, because our products are increasingly being sold in bundles and security must be ensured at all levels.

8. What Trends Do You See That Could Influence Our Products in the Future?

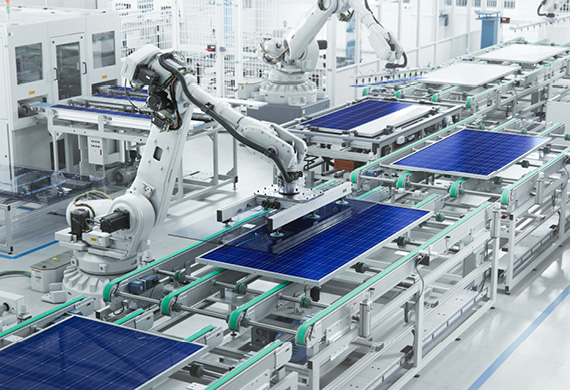

Robin: As I said earlier, information security is an important issue that will continue to keep us busy in the future. Update cycles are becoming shorter and cooperation between the user and manufacturer of the software is becoming more intensive. Artificial intelligence will also play a major role, of course; we are already using AI in our projects, such as in automatic fault detection for solar cells, for example. AI will also change the way we work when evaluating large amounts of data. As its use becomes more commonplace, the cloud will also become increasingly relevant as an infrastructure for manufacturing execution system. I can well imagine that hybrid systems of local production control and long-term data archiving, including reporting from the cloud, will be very interesting for many of our customers.

Natalie: The major topics of cybersecurity and AI are already influencing our products. With AI in particular, we are looking at how the new tools can usefully support us in our work and how our customers can benefit from them. In industry-specific terms, I see a trend in the semiconductor market that manufacturers also want to connect backend systems to their host systems in a SEMI-compliant manner. This poses major challenges for our customers, because the GEM300 SEMI standards have been developed for the frontend. One example: At the backend, a workpiece can be added to the system, but dicing produces many units of material output. This places new demands on traceability. Our customers need a partner who has experience in implementing SEMI standards and is able to interpret and implement them a way that matches their systems.

Vanessa: Cybersecurity will decisively determine the software sector in the coming years, because requirements and risks are constantly increasing, especially with regard to the increased use of AI, e.g. in the form of neural networks or LLMs. This will steadily increase the need to make our software even more secure and less vulnerable. What is currently still regarded as a nice-to-have USP could soon be the decisive factor when choosing the right software provider. Edge computing will also become more important, especially when machine data is collected constantly and also used for digital business models. It is still early days for equipment manufacturing in this respect. Companies are experimenting with it, but it is not yet being used across the board, they rather act as laggard late adopters. However, as soon as the volume of data that needs to be processed in real time increases, concepts must be created where efficient and high-performance data processing can be guaranteed even for applications with poor network coverage and high latency times. Low-code and no-code applications are another trend. These will continue to increase in line with the need for software applications, while at the same time the available number of skilled workers is decreasing, and the requirement for cost-effective and rapid development cycles also needs to be considered.

9. Last but Not Least, Let’s Look Towards the Future: What Is Your Vision for the Use of Industrial Software in Equipment Manufacturing and by Factory Operators in 10 Years’ Time?

Vanessa: In ten years we will still see industrial software that monitors, digitalizes and accelerates processes, and provides added value through real-time analysis of machine data by providing the basis for new business models. However, we will actually see a much higher level of automation here, as trained neural networks can feed off a significantly higher volume of data than today. Recommendations will be derived by the systems automatically and people can use them as a reliable data basis for making decisions. The complexity of applications will continue to increase due to the seamless networking of machines, things and factories, which requires powerful and intelligent preparatory processing. Factory operators and manufacturers will work together even more closely, as there will also be clear regulations on the handling of data, which will result in new potential on both sides and the boundaries will become more blurred.

Natalie: My vision for industrial software in ten years is that equipment manufacturers can use ToolCommander® for equipment control just as naturally as we use Word or Excel as office programs in administrative areas today. I hope that, having excellent features in terms of usability and user documentation, the implementation is not just a task that needs to be done, but can even be fun. I hope for the industry-specific SEMI-compliant connectivity via SECS/GEM, GEM300 or EDA to also develop in this direction. Even though the complexity of the standards will still require explanation, we will get a lot closer to this goal with AI and our FabLink® product development as an integration solution.

Robin: In factory automation, we will still be collecting data through machine data interfaces in 10 years, but how we evaluate and visualize this data will change dramatically. For example, instead of using large screens, we could visualize data on AR glasses with the help of AI. The level of automation will also continue to rise, for example AGVs and robots, which will independently receive and solve tasks from the line controller without lengthy programming or commissioning. Line controllers and interface integrations will provide the backbone for intelligent subsystems that perform their tasks autonomously.