The energy revolution is well under way, where green hydrogen plays a key role. At Kontron AIS GmbH, we are actively shaping this change and contributing our expertise to the H2Giga project, which runs until June 2025 — a program funded by the Federal Ministry of Education and Research (BMBF). Our goal is to work together to ensure a sustainable supply of green hydrogen to Germany. The focus is on the large-scale production of high-temperature electrolyzers (HTEL modules), which represent an important step towards an emission-free future.

With modern IT infrastructure, we contribute to quality assurance in the mass production of high-temperature electrolyzers. In doing so, we support the main goal of the project: the efficient and environmentally friendly production of hydrogen in large quantities. These innovative HTEL manufacturing plants are the key to producing hydrogen on a large scale efficiently and in an environmentally friendly way. Our IT solutions record and monitor all production steps to make the manufacturing process as smooth as possible.

With our project focus on connectivity, cloud-based MES and an analysis platform, we are making a contribution to the industrialization and development of technologies that enable a climate-friendly and sustainable energy future for the next generations.

1. Connectivity – Efficient Networking for Enhanced Security

A central component of our project quality assurance solution is the secure and reliable networking of manufacturing machines. We use the latest IoT technologies to enable seamless data transfer to the cloud. This creates the basis for material tracking, evaluations and end-to-end reporting.

The key to data transfer is an edge device. As a small but powerful device, it connects production machinery to the cloud. As a result, it forms the central interface for secure data transmission. This device is securely managed using our device management cloud application. The secure connection of all devices in the network plays a decisive role in enabling seamless data acquisition.

Key advantages of device management include:

- Central management of all edge devices: We monitor the operating status and available services of all connected devices to achieve optimal operation.

- Secure operation without an internet connection: The use of edge devices does not require a direct internet connection to the production systems. This significantly increases security, as sensitive production data does not have to be sent directly over the internet.

- The highest security standards: Our edge devices are equipped with a hardened operating system that is optimally protected thanks to continuous updates and strict access controls.

In addition, applications on edge devices run in isolated containers. These containers offer enhanced flexibility and security as they work independently of each other and can be quickly adjusted as needed. As a result, the entire system remains robust and future-proof, which is perfect for the requirements of industrial production.

Remote connectivity: Secure remote access and flexible data management

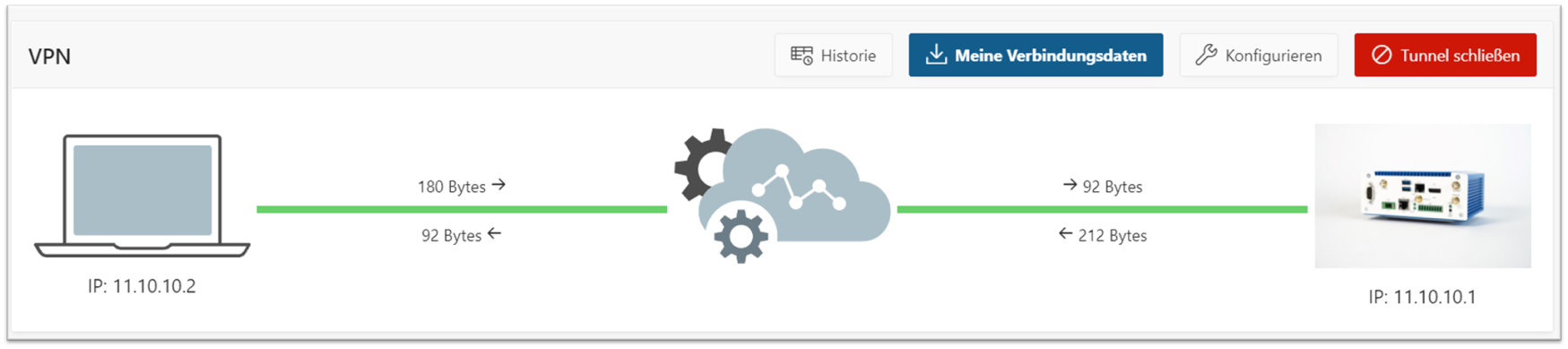

Digitalization in manufacturing requires more flexibility today than ever before. In order to efficiently control production processes and minimize downtime, it is essential to be able to access systems remotely. This is exactly where our remote connectivity solution comes in, enabling us to provide secure remote access to manufacturing systems anywhere, anytime. An encrypted connection to the edge devices is established using a virtual private network (VPN) so that the machines can be securely monitored and maintained. The edge device acts as a VPN gateway and ensures that access is flexible but also secure.

Here is a summary of the main functions:

- Secure connections to the machines: The encrypted VPN connection ensures that access to the machines remains protected and reliable.

- Central user administration: User rights are controlled using our digital transformation solution. That is how we ensure that only authorized persons have access to these systems.

- Flexible access: Regardless of whether via console or desktop, remote access makes it easy to manage and maintain edge devices without having to be on site.

Moreover, our low code integration solution offers another powerful way to integrate IT systems into the manufacturing environment. This interface integration solution has been specifically designed to provide a seamless connection between various data formats, protocols, and interfaces. It offers a comprehensive set of modules for configuring and managing data flows.

These are the main features of the integration solution:

- Graphical configuration of data flows: With a low code approach that allows configuration instead of programming, data flows can be designed simply and visually.

- Use of prefabricated components: Existing components can be flexibly linked together to create custom-built logics for specific production requirements.

- Interface for data acquisition and evaluation: An API based on a REST interface makes it possible to provide data to external reporting systems. The focus is on monitoring process data.

As part of the HTEL funding project, the following functionalities have been implemented successfully:

- Porting to Linux: The system now runs on Linux-based edge devices, which increases compatibility and security.

- Docker container solution: The applications run in isolation in Docker containers, which provide additional security and flexibility.

We use these technologies to create a future-focused, secure and efficient infrastructure that enables both direct and remote access to HTEL manufacturing systems.

2. Cloud-Based MES: Extension of FabEagle® Next Frameworks for Production Control

FabEagle® Next Frameworks is part of the funding project that pursues the central goal of developing a new cloud-based MES. This is designed to meet the requirements of a service-oriented architecture (SOA) and at the same time provide a flexible, scalable and secure solution for production control.

One of the central elements of this new MES solution is user management. In an SOA environment, numerous services run in parallel, which makes managing rights and access controls a particular challenge. To cope with this, we rely on modern technologies such as OAuth and KeyCloak for secure authentication and efficient rights management.

In addition, long-term tests have been carried out to ensure the fail-safety of the demonstrator:

- Long-term tests to evaluate system stability

- Notification simulation for more meaningful test results

- Central evaluation of log files to monitor and analyze system performance

- Usability tests to further improve the user-friendliness of the framework for software developers

An integration test with a demo customer confirmed that data transfer was error-free, that the error handling was correct and that there was compatibility with other systems.

Another milestone was scaling the run-time of new services. The focus here was on the automatic provision and approval of resources as well as monitoring availability to ensure continuous and efficient use of the IT infrastructure.

Docker and Docker Compose: Managing containers efficiently

We use Docker and Docker Compose; two powerful tools that make it possible to run various applications in isolated containers. Configuration parameters such as port mapping and environment variables can also be defined. This makes it much easier to deploy and scale the various MES services.

Using Docker Compose, complex applications can be built and configured quickly and easily from multiple Docker containers. The low code approach makes it possible to start and manage all services from configuration files, which is particularly advantageous for wide-ranging MES services.

3. Analytics Platform: Efficient Data Preparation and AI-Based Support

An essential part of our development work during the project is the development of an analysis platform, consisting of a meta-keyconcept. In the future, this concept will make it possible to efficiently filter and group production and process data in order to gain valuable insights.

Meta-Key Concept: Structured Data Analysis for Precise Evaluation

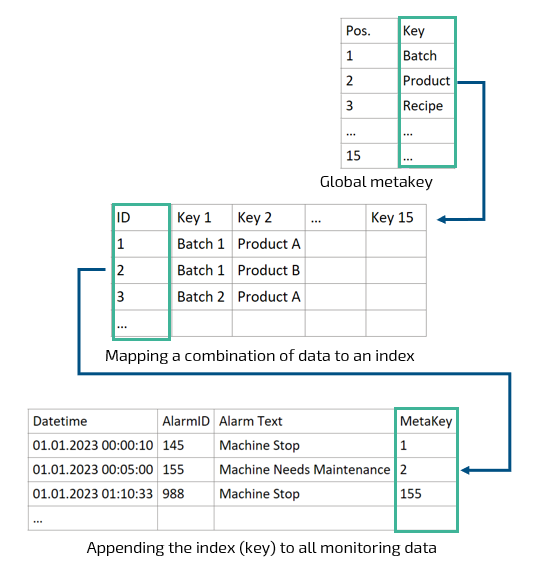

The meta-key concept makes it possible to define global key values with which machine and process data can be filtered or grouped. Each key set creates a unique key that is assigned to monitoring data (alarms, process data, machine status, etc.). This gives us two major advantages for data analysis:

- Key values for filtering and grouping: Machine data can be specifically assigned and filtered or grouped according to predefined key values.

- Unique keys for precise analyses: Each combination of keys creates a unique meta key, which ensures exact identification and categorization of data.

This concept will help facilitate the analysis of high volumes of data. It also makes a significant contribution to creating more accurate and meaningful reports that can be used to optimize processes.

AI-Supported Documentation Bot: Quick Answers Using Intelligent Search

Another important feature is the development of an AI-based chat and search function in the demonstrator, which offers users quick and intuitive access to specific questions about the documentation. The AI documentation bot searches the existing documentation and provides precise answers based on a large language model (LLM), which has been trained using extensive data sets. The prerequisite for this is a structured knowledge database, which serves as a basis for training the model. To achieve this, question-answer pairs are defined in advance to cover the most frequently asked questions and answers.

These are the benefits of the AI documentation bot:

- Quicker answers: Users receive relevant information in a very short time without having to search through all the documentation themselves.

- More efficient help: The bot provides specific help to questions, significantly increasing the level of support and user satisfaction.

- Easy to use: After entering questions using the search function, the bot immediately provides a suitable answer.

Chat Function: Communication and Real-Time Support

A chat function has also been implemented that enables direct and uncomplicated communication between users. This feature not only offers the advantage of real-time support, but also promotes community building by setting up discussion forums.

Ultimately, by combining a powerful analytics platform with an AI-based chat solution, we want to create a modern and efficient future-safe environment that takes both data processing and user support to a new level.

Outlook

The funding project will run until June 2025 and the results achieved so far show the potential of the technologies and systems that have been developed. At a big status conference in September 2024, all project partners presented their progress so far, shared experiences and defined the next steps. These regular meetings are an excellent opportunity to promote the transfer of knowledge and technology between the project partners and to consistently pursue shared goals.

Leading up to the end of the project, the focus in the coming months will be on further developing and optimizing the demo system to further industrialize production processes for high-temperature electrolyzers.

With HTEL manufacturing systems and our digital infrastructure, we are creating the basis for a climate-friendly energy future in the gigawatt range. Secure connectivity, modern cloud-based MES solutions and intelligent analysis platforms enable efficient and scalable production of green hydrogen. Our involvement in the H2Giga project shows that industrializing this key technology is both possible, and is an important step towards an emission-free future.

Partner:

Sunfire GmbH

DECHEMA Forschungsinstitut - DFI

DBI Gas -und Umwelttechnik GmbH

TU Freiberg - Technische Mechanik - Festkörpermechanik

IMK automotive GmbH

Xenon Automatisierungstechnik GmbH

SMA Solar Technology GmbH (joined subsequently)