“3D-FF — Demanding free-form coating of flat and 3-dimensional substrates using inline sputtering technology”, subproject: “Integration of calculation and simulation modules into system software for complex freeform coatings”

Research partners: Fraunhofer Institute for Organic Electronics, Electron Beam and Plasma Technology FEP, LSA GmbH Leischnig Schaltschrankbau Automatisierungstechnik, Von Ardenne GmbH, SeeReal Technologies GmbH and TU Dresden (Institute of Solid State Electronics and Mathematics), Kontron AIS GmbH

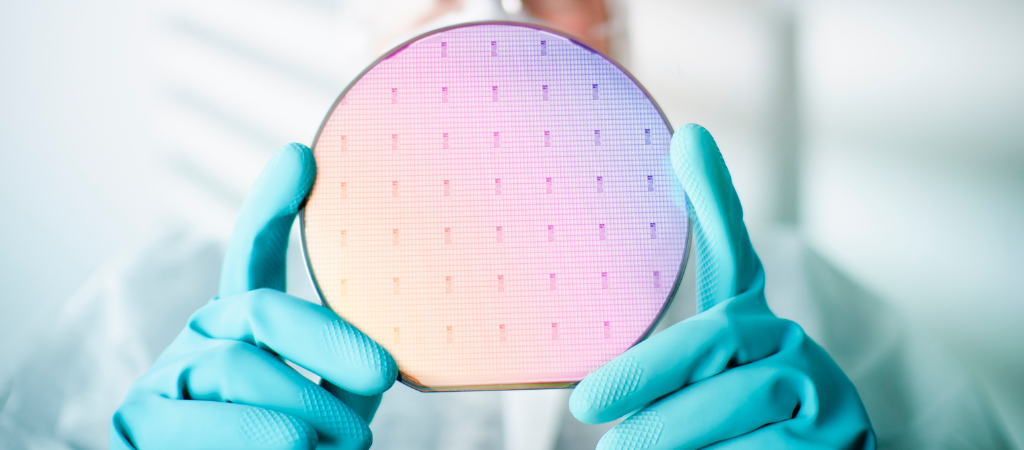

Coating technology plays a decisive role in the production of photonic components for optical applications. Continuous improvements and innovations in inline magnetron sputtering technology are required to enable the precise production of large-area coating systems. As part of the 3D-FF joint project, extensive investigations were carried out to expand the possibilities of coating technology. The software expertise of Kontron AIS and the integration of calculation and simulation models into the system software played an important role here. In this blog post, we take a closer look at innovations in coating technology and the crucial role of software in achieving these advances.

The Development of New Control Software

As part of the project, a new generation of the ToolCommander® control software was developed, with great emphasis being placed on simplicity and flexibility. The aim was a software framework for system control that is intuitive so that new developers learn to use it more quickly and collaboration with external development teams is made easier. Integrating third-party modules, exchanging individual modules, and integrating data analysis functions resulted in software which is highly adaptable. This allows users to adapt the system according to their own expertise or completely replace individual modules.

A significant advance was the creation of a new standard for machine technology with ToolCommander®. This enabled other engineering companies to develop their own machine software based on the ToolCommander® platform. This open and modular architecture has created a new market for software solutions in coating technology and paved the way for further innovations.

With the new generation of the ToolCommander® software framework, coating technology has taken a decisive step forward. The innovative control software provides precision, flexibility, and adaptability, which are essential for the production of large-surface coating systems for optical applications.

Simulations in Coating Technology: The Key to Precise Free-Form Coating

To enable the precise coating of 3D substrates, extensive simulations of free-form coating were carried out. These took into account the layer thickness distribution during the coating process and made it possible to determine specific control parameters for the specific layer profiles. Adapted control software was developed for free-form coating with ToolCommander®. The change in the technological basis made it easier to replace the individual modules and to integrate data analysis functions, which are part of the evaluation of coating processes. The simplified structure is shown in Fig. 1.

The four components are:

- Operations: Visualization of the user interface for machine users. All visible functions are located here.

- Object pool: Presentation of the system’s data technology basis. The most important data that is required is consolidated here. In addition to the actual and target values of the system, this also includes data from recipes, orders, and other data structures required for operational reasons.

- Database: Since the object pool is responsible for saving the data, it is stored in a relational database in the current design.

- Kernel: This application is responsible for system control and is the only one with access to the system's hardware, such as actuators and sensors. The kernel is the critical component and works even without the remaining components as long as all necessary data is available. Communication takes place exclusively via the object pool.

Inversion of Control (IoC): Revolutionary Solutions for Dependencies in Software Development

Inversion of control has the potential to fundamentally change the way we develop software. In the past, software components were closely linked and changes at one point in the code often had far-reaching effects on other areas. This led to a considerable amount of code coupling and made maintaining and extending software more difficult.

IoC frameworks represent an innovative approach to solving this problem by reducing the dependencies between software components. Instead of the code having control, IoC reverses the dynamics: the user writes the code and the framework calls it at the right time. This allows for more flexible management of the lifecycle and creates new ways of resolving dependencies.

An important component is the IoC container. The container takes on responsibility for the implementations and allows the dependencies specified in the constructor of a component to be correctly resolved. It separates the components from each other and improves the maintainability, extensibility, and testability of the software.

Thanks to IoC frameworks and the use of IoC containers, developers can focus on developing high-quality code logic while the software framework takes over the task of managing and resolving dependencies.

Values With Units: Consistency and Flexibility in Software Development

Values with attributed units enable more precise modeling and greater reliability in the software. To achieve this goal, an innovative approach was chosen in the new generation of ToolCommander®. Instead of just looking at purely numerical values, parameters, and actual and target values, are modeled as values with units. This demonstrates the relevance of the units of measurement and ensures a high level of consistency in the software.

Implicit conversions between different units can also be performed in this way, which facilitates data processing and reduces potential programming errors. A practical example is temperature measurement. By using values with units, the temperature can be measured in kelvins but displayed in Celsius on the user interface without programmers having to make explicit conversions.

Another advantage of using values with units is error avoidance. Logical tests can prevent potential programming errors that can occur when incompatible types are to be calculated together. For example, calculating a value in kilograms with a value in Celsius would produce an inconsistent result. On the other hand, calculating convertible values with different units, e.g. pressure in pascals with pressure in torrs, presents no problems.

This approach significantly improves consistency, flexibility, and error prevention. Developers can focus more on the actual logic of their applications, as they no longer have to pay constant attention to unit conversions. Values with units are an important step towards intelligent and intuitive software development and were therefore incorporated in the development of ToolCommander® as one of the innovative features.

Hierarchical Modeling in ToolCommander®: Hierarchical Modeling in Toolcommander®: Simulation of the Machine Structure With Nodes

Simulation of the machine structure is an essential part of software development in ToolCommander®. Here, nodes are used in a hierarchical structure to show the relationships between the various elements of the system. These elements can be, for example, valves, motors, processing chambers, or even the entire machine. All nodes are based on a common base class, the node class.

The structure of the machine is modeled in the system on the basis of relationships between the nodes. To illustrate this, Fig. 2 shows an example of such a system.

Nodes are used in a hierarchical structure to show the relationships between the various elements of the system. This method enables precise modeling and creates an intuitive development environment. The hierarchical structure creates a close connection between the real machine structure and the software and improves reproducibility and comprehensibility. It also enables modular and scalable development, as new components can simply be added or existing nodes modified without affecting the overall structure.

Mapping the machine structure with nodes in ToolCommander® enables precise modeling of systems and machines in the software. The hierarchical structure demonstrates the relationships between the individual elements and creates an intuitive development environment. This connection between the real world and software enables more efficient development, better maintainability, and an improved user experience.

ToolCommander® takes software development to a new level of more precise and realistic visualization of machines and systems. Through the continuous development of these innovative approaches, coating technology is constantly being improved and new standards are set.

User-Friendliness and Intuitive Interaction: The Design of the User Interface In ToolCommander®

In ToolCommander®, great emphasis was placed on creating a careful information architecture in order to give the various data in the system a meaningful structure.

Another important aspect was the development of an interaction concept that represents the actions and needs of users. The user interfaces were designed to be both compelling and intuitive so that developers can easily convert them into code later on.

To ensure a consistent user experience, a UI style guide was created that defines the basic aspects such as color palettes, fonts, and font sizes. This ensures that the user interface has a uniform appearance.

The 3D-FF research project opened new paths in improving magnetron sputtering technology to enable high-precision coating systems for photonic components.

A milestone in this process was the development of the new generation of ToolCommander® control software from Kontron AIS. This not only enabled faster adaptation and extension of machine technology, but also laid the foundation for integrating simulation models. These simulations of free-form coatings provided valuable insights and made it possible to determine specific control parameters. Using inversion of control (IoC) has made software development more flexible and easier to maintain. Unit values helped to improve the consistency and flexibility of the software and avoid errors.

Modeling the machine structure with nodes enabled more precise and realistic visualization of the systems. The hierarchical structure and the clear organization of the components created an intuitive development environment. At the same time, the design of the user interface has been carefully thought out to ensure user-friendly and intuitive interaction.

These advances have raised coating technology to a new level and open up a wide range of applications for photonic components in optical applications.

With the new development of ToolCommander®, a new generation of the machine framework was created which makes highly complex coatings possible. The modularization and integration of external modules also enables cooperation with partners on solving complex tasks. As a result, Kontron AIS is in a position to break into new areas and industries that have so far not been viable.

Would you like to find out more about the various Kontron AIS research projects? Then send us an e-mail.