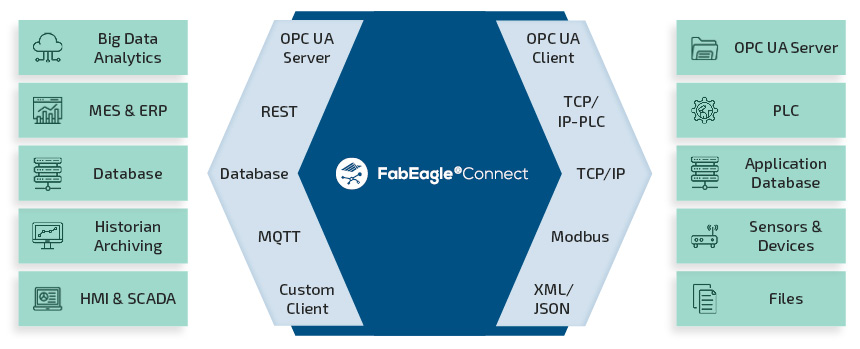

With FabEagle®Connect, you can implement configurable and reliable interfaces such as OPC UA, REST or TCP/IP for your machines and IT applications. Our integration solution helps you meet IT requirements regardless of the age or manufacturer of your machines and devices, especially as automation levels increase.

With flexible components for interface protocols and data processing, FabEagle®Connect allows you to effectively handle specific and complex requirements.

Integration Software FabEagle®Connect – Your Benefits

- Easily integrate machines through low-code configuration dialogs for interfaces

- Save costs by utilizing and connecting different interface protocols

- Increase data security with regular feature and security updates

- Respond flexibly to changes with simple extensions of existing interface configurations

- Future-proof with scalability in parallel FabEagle®Connect applications

- Implement custom logic and interfaces modularly

- Add logic functionality to process digital signals for older machines

FabEagle®Connect: Your Interface Integration Software for Multiple Applications

FabEagle®Connect is comprehensive software that standardizes the integration layer between the shop floor and IT systems, simplifying the integration and maintenance of various interfaces. Complex interfaces and logic are easy to implement using flexible components.

Many companies operate machines and systems requiring special non-standard interfaces. FabEagle®Connect is the perfect solution for this. With specialized code components, you can reliably connect your older machines and custom solutions.

The Kontron KBox A-251-AML/ADN is an optimized industry PC designed specifically for gateway applications. As part of the Connect IoT Bundle, the KBox comes with FabEagle®Connect pre-installed, so you’re ready to start right away.

Overview of Components and Features of the Integration Software

FabEagle®Connect provides you an open, comprehensive platform for interface integration. With ready-made components and guided configuration dialogs, you can efficiently implement and manage complex integration projects. FabEagle®Connect operates across various operating systems, including Windows 10, Windows 11 or with Docker and Linux and KontronOS.

| Data interfaces for your integration projects | Data access via file and database interfaces | Data processing using code components |

|---|---|---|

|

|

|

- OPC UA Client

- OPC UA Server

- REST Client

- TCP/IP Server and Client

- Custom Client

- MQTT

- ActiveMQ

- RS232

- PLC-S7

- Modbus

- XML/JSON

- SECS/GEM Host

- File Reader

- SQL Databases

- MES

- ERP

- Historian Archiving

- HMI & SCADA

- Big Data Analytics

- Database

- OPC UA Server

- Application Database

- PLC

- Files

- Sensors & Devices

Your Contact Persons for Interface Integration