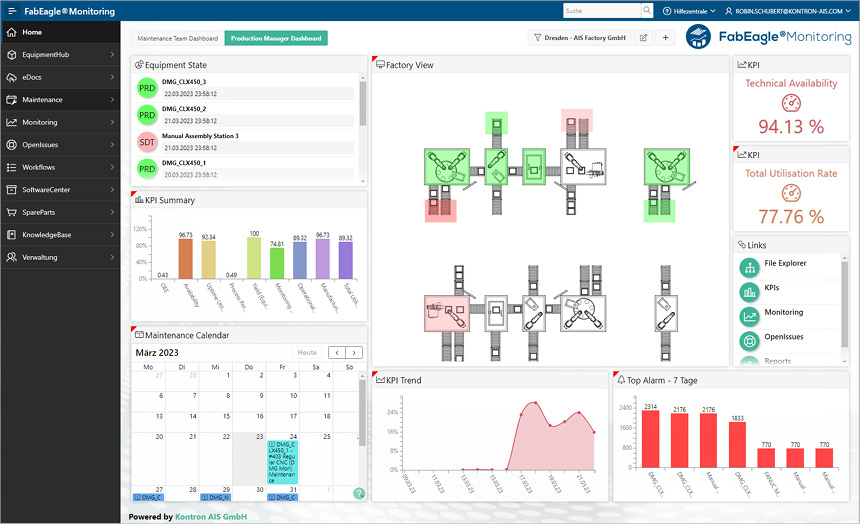

FabEagle®Monitoring supports your shop floor management throughout the entire factory. With this monitoring system and machine and production data collection (MDA/PDA), you get a clear visualization of your machines and systems. It focuses on monitoring and displaying machine states, throughputs, alarms and maintenance activities – all within customizable dashboards and reports. This allows you to always keep track of production efficiency and maintenance status, recognizing necessary adjustments early on and optimize your processes step by step.

FabEagle®Monitoring Shop Floor Management Software – Your Benefits

- Visualizations in a personalized dashboard reduce response times

- Comparison of machine types or entire production areas enables productivity to be optimized

- Automatic calculation and visualization of OEE simplify evaluation

- Documentation and search functions for best practice information speed up maintenance

- Clear information management promotes teamwork

- Factual comparison of planned figures and KPI calculation increase effectiveness

- Visualization of machine alarms and malfunctions shortens response times

- Automatic maintenance planning reduces downtimes and malfunctions

- Prepared workflows and checklists simplify documentation

FabEagle®Monitoring Addresses Your Wide Range of Shop Floor Management Tasks

Structured data collection is the foundation for data-driven process optimization within your company. FabEagle®Monitoring offers you the perfect platform to centrally acquire and analyze all machine and operational data.

Optimized maintenance planning and execution can significantly reduce your downtime. With FabEagle®Monitoring, you can efficiently plan and document your maintenance activities and benefit from best-practice documentation that quickly guides you to solutions when problems arise.

Effective teamwork begins with clear communication of essential information. FabEagle®Monitoring dashboards provide you and your team with an overview of machine states, trends and alarms, ensuring that important information is always transparent and accessible.

A pilot project with FabEagle®Monitoring quickly gives you deep insight into the operational states and utilization of your machines, allowing you to identify production optimization potential and act quickly.

Andon boards are preconfigured dashboards that support your lean management. By adding an Andon board to FabEagle®Monitoring, you can visualize production goals, throughput and orders in progress. This keeps your employees motivated and allows you to react quickly to irregularities. You can view current production states against planned and produced quantities, view current production orders, and identify backlogs. You also gain visibility into machine states and alarms, allowing you to respond quickly to irregularities and malfunctions.

FabEagle®Monitoring can be used internationally and is available in seven languages: English, French, German, Spanish, Dutch, Mandarin and Russian. Users can set the application language of the shop floor management software to their native language, increasing adoption, easing operation and reducing misunderstandings.

Your Contacts for Factory-Wide Shopfloor Management