ToolCommander® is the open software framework for equipment control and visualizations for cluster, inline and batch tools in production and research. Its modular design makes ToolCommander® easy to customize to the individual requirements of a wide range of industries. Thanks to our open approach you can realize your equipment control entirely on your own or together with our team that has over 35 years’ experience of implementing control solutions for the semiconductor, coating and photovoltaic industries.

ToolCommander® – Your Benefits

- Efficient development with C#/.NET framework and WPF visualization

- Accelerated programming thanks to extensive features and component library

- Comprehensive development and product support

- Ongoing simulation and testing opportunities available from the start of development

- Trend module for process monitoring, quality assurance and predictive maintenance

- Integrated touch optimization throughout for quick access (SEMI E95)

- Optimized visualization for production and service

- Unique interlock handling, system and I/O diagnosis with live debugging

- Comprehensive troubleshooting support

- SEMI standard compliance

- SECS/GEM and GEM300 integration-ready

- Know-how protection with in-house developments

- Configurable user rights

Efficient Equipment Control with Toolcommander®

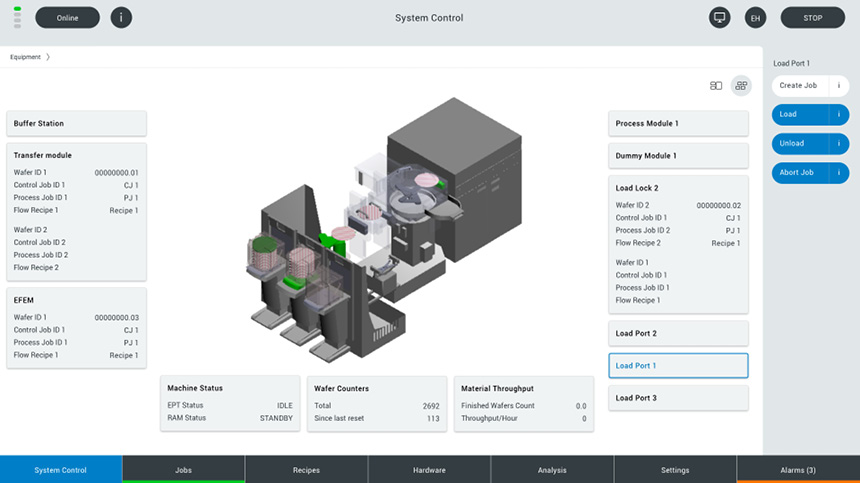

From material feeding scheduling and recipe execution to monitoring process parameters – ToolCommander® offers you SEMI-compliant equipment control for cluster tools in the semiconductor industry.

With ToolCommander®, you can control every batch tool including the installed components (e.g. valves, motors) and the management of the batch process for best results, for example for vacuum thin film applications.

In inline tools, for example in the glass or photovoltaic industry, ToolCommander® not only provides process control and visualization, but also overarching control of material movement sequences.

Features at a Glance

ToolCommander® offers you a wide range of proven features for the reliable and fast implementation of your equipment control in the fields of semiconductors, vacuum coating, solar, LED and MEMS.

Basic functionalities

ToolCommander® has an integrated user management system with configurable user rights. This allows you to maintain control over access to the equipment control system at any time.

Alarms and messages are visualized by ToolCommander® and functions offered for alarm-related actions. An archive for all alarms, warnings and messages provides visibility and traceability.

Configure a clearly structured presentation of live and historical process and machine data in graphs and tables. If required, you can select specific data for export from the ToolCommander® data archive to wherever you need it.

Visualization

The ToolCommander® GUI with full touch operation (SEMI E95) allows easy access to the control system on the equipment itself – from an overview of the tool and recipes to live debugging on the machine itself. The transparent real-time visualization of interlocks gives operators working in manual mode the necessary information about which control activities are currently possible and shows the status of the relevant conditions. You can change the language at any time during operation.

Control

Scheduling in ToolCommander® includes the optimized performance sequence of the individual work steps in real time. This way, we meet the requirement that priorities vary within different equipment series. Choose between flow recipes and algorithm-based optimization and, with our help, you can find the perfect path through the equipment.

With ToolCommander® material management, you can identify and track materials and assign individual jobs.

ToolCommander® controls and manages the equipment’s tasks. With regard to job management (E94) in the semiconductor industry, both control jobs (CJ) and process jobs (PJ) are managed in accordance with SEMI.

In addition to creating and managing process recipes and displaying the recipe status, ToolCommander® also controls your flow recipes. You decide who can access your recipes and to what extent.

Commissioning and service

ToolCommander® gives you full simulation capabilities down to I/O level and hardware endpoints. This high level of detail enables early fault detection in the development process, step-by-step commissioning and easy replacement of the systems to be simulated. Individual values can be manipulated specifically for test scenarios. This saves valuable time during commissioning and when identifying faults during servicing.

Manual operation allows the control and parameterization of individual components, giving you a powerful tool for commissioning and maintenance. Within the ToolCommander® manual control dialogue, actual and target values are displayed in real time, as are interlocks.

Diagnosis and troubleshooting

In addition to diagnostics for all digital and analog inputs and outputs, operators can use ToolCommander® to carry out manual channel controlling to identify sources of faults.

The ToolCommander® system diagnosis makes it possible to monitor all equipment control processes and offers the option of live debugging. Maintenance costs are significantly reduced and service engineers can correct faults on the equipment itself, thus keeping downtimes to a minimum.

Logging in ToolCommander® takes place in a Postgres database. Data on alarms, processes and materials are stored here. In addition, domain and debug logging is available for tracking all control processes and for optimum troubleshooting.

SEMI Standard Compliance for the Semiconductor Industry

With the integrated support for all relevant SEMI standards, ToolCommander® enables safe and standards-compliant placement of your equipments in semiconductor factories. With our FabLink® interface solution, equipment integration is performed in accordance with the SECS/GEM, GEM300 and EDA standards. Further detailed information on the standards and their application can be found here.

| SECS/GEM (200 mm) | GEM300 (300 mm) | EDA (Interface A) | Common Standards |

|---|---|---|---|

| Visualization (GUI) |

|---|

|

ToolCommander® also complies with the SEMI standard for consistent and intuitive operation. ToolCommander® is based on modern UX design for clarity and fast operability and offers convenient touch capability at all operating levels. This shortens user training times and minimizes the error rate in operation.

| Cybersecurity |

|---|

|

|

|

With our ToolCommander® equipment control system, you fulfil the requirements of the SEMI cyber security standards. We support you on the path to SEMI compliance and help you to implement the Cyber Resilience Act at an early stage:

- Security is at the centre of equipment control system development right from the beginning

- New up-to-date equipment control software, including retrofits for existing tools in long-term operation, in order to maintain service and provide regular updates

- Modern connectivity solutions to eliminate critical dependencies

- Provide cybersecurity relevant information for fast and easy risk assessment

These measures give you the security to operate your systems in a stable and protected manner in the long term.

Your way to equipment control with ToolCommander®

With ToolCommander® and over 35 years’ experience of programming equipment control systems, we are your full-service partner and offer you: Consulting, specification, realization, test period, commissioning, maintenance.

We support you on the way to your equipment control. Exactly how much we do for you is entirely up to you.

We develop your equipment control with you based on ToolCommander® and support you with training, consulting and support. This allows you to remain flexible and to distribute your work packages for maximum efficiency according to your time capacities and experience.

Develop your equipment control entirely on your own and completely independently with the ToolCommander® software framework. We are always there if you need us and offer you training, consulting and support.

If you have insufficient time and experience, feel free to call on our over 35 years of know-how in programming equipment control systems for mechanical engineering. We will develop your ToolCommander® based equipment control precisely to your requirements.

Your contact persons

You may also be interested in

FAQs: Semiconductor Automation – Basics & Terms

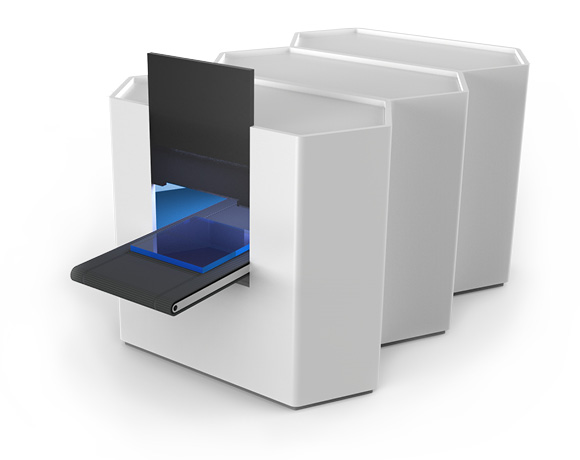

A loadport is a standardized interface in a semiconductor production equipment through which wafer carriers (e.g., FOUPs at 300 mm or SMIF pods at 200 mm) are automatically docked to the equipment. It forms the transfer point between the material handling system (AMHS/OHT/operator) and the equipment.

A loadport recognizes the carrier, checks its ID and status, performs automatic docking, and opens the carrier under clean room conditions. Wafers can then be transferred to the tool via the internal handling system (e.g., robotics). A semiconductor manufacturing equipment can have one or more load ports.

The abbreviation “EFEM” stands for “Equipment Front End Module” and is an important component in semiconductor manufacturing equipment.

The EFEM is a handling platform that accepts material via load ports, identifies the individual substrates via a reader, and prepares them for processing by aligning the substrates using (pre-)aligners. Some EFEMs also have a buffer station or a cooling station to cool the wafers after processing, as they are still too hot to be transferred back to the carrier.

A subsystem is a functionally distinct module within a complex manufacturing system that performs a clearly defined task and communicates with the higher-level control system via standardized interfaces.

Subsystems offer reusable architectures within a system and, in accordance with the SEMI E30 standard, have clearly defined standard functions and follow the state models.

Scheduling is particularly important for GEM300 equipment, which handles complex job management with control jobs and process jobs. Schedulers plan the most efficient sequence for processing jobs and the best route for substrates through the equipment. Scheduling offers several maximization options. Typical maximization goals for a system in a semiconductor fab are throughput (WPH), system utilization, quality, or compliance with technological restrictions (e.g., temperature ramps, queue time constraints).

Dispatching, as part of scheduling, is responsible for the actual execution of the individual steps.

FAQs: ToolCommander® – Equipment control for the semiconductor industry

Equipment controls in the semiconductor industry are characterized by extremely high requirements for process stability, precision, and traceability. Equipment in this area has bills of materials comprising several thousand components. It must also be ensured that the integrated systems from a wide variety of manufacturers can communicate seamlessly with each other.

The frontend usually uses cluster systems. These consist of several subsystems that the control system must manage:

- Loardport

- Transport system

- Reader

- Aligner

In addition, the equipment control must have the following higher-level software functions:

- Scheduling

- Host integration (SEMI conform: SECS/GEM, GEM300, EDA)

Due to the high functional and data-driven requirements, PLC systems alone are usually not sufficient, but can be used as an integral part of an IPC control system.

Typical production equipment in the front end of the semiconductor industry are cluster tools. These systems are highly complex in design. In addition to several process chambers, they also feature an upstream material feeding system, driven by the increasing degree of automation.

This comprises one or more load ports for receiving the carriers and an EFEM in which substrates are identified by a reader and oriented using an aligner and then transferred to a load lock by a robotic transport system.

The load lock acts as an airlock between the atmospheric area and the vacuum area of the system.

This is followed by a vacuum chamber with a second robot that distributes the substrates to the respective process chambers in a targeted manner. The number of process chambers and load ports can vary depending on the type of system. In some systems, the process chambers are also directly connected to the first transport system.

In back end production, the structure of the systems is more diverse, as processes can vary greatly.

A framework for programming equipment controls in the semiconductor industry provides structure, reusability, and security in the semiconductor environment, which sets the highest demands regarding reliability, precision, and standard compliance. A major strength is that the various subsystems interact seamlessly in the defined processes. This makes the complexity of the equipment control project manageable. At the same time, it reduces development effort and the likelihood of errors. Furthermore, it simplifies SEMI compliance certification, enables easier maintenance and updates, and allows for rapid development of new subsystems or process modules. This shortens time-to-market and keeps equipments more robust and easier to automate throughout their lifecycle.

ToolCommander® is mainly used in the semiconductor industry in front-end and back-end processes and in vacuum coating. Its modular architecture also allows it to be used in industries such as PV, LED, MEMS, photonics, and even agriculture.

The decisive criteria for using ToolCommander® are usually the high complexity of a system, the desire for flexibility in terms of quick adjustments to the equipment and thus also to the equipment control, or the wish for independence.

FAQs: ToolCommander – Einstieg & Voraussetzungen

Yes, you can book a demo appointment with us to get an impression of a finished control solution with ToolCommander®. In addition, you can use our tutorial to test the programming of your equipment control with ToolCommander® yourself.

The prerequisite is proficiency in C#/.NET. Visualizations are implemented using WPF, but web interfaces are also possible. Knowledge of the peculiarities of mechanical engineering (e.g., double triggering of a signal due to bouncing) is an advantage.

Knowledge of SEMI standards is advantageous, but not essential. We offer training courses on SEMI standards, workshops on the optimal implementation of your project, and coaching during implementation if you decide to do your own programming. The ToolCommander® framework itself provides guidance on standard-compliant programming.

![[Translate to English:] Logo Beckhoff](/fileadmin/ais/06_Referenzen/Logos/Website_Referenzlogos_Slider_168x56px_Beckhoff.png)