FabLink® is your standard-compliant solution for implementing SEMI standards for vertical integration of production equipment in accordance with the SEMI Generic Equipment Model (GEM), GEM300 and EDA standards. With SEMI-compliant interfaces, you can quickly and easily integrate your machines into semiconductor, PCB, LED, flat panel and OLED factories. The SEMI PV standard, adapted to the photovoltaic industry, is used for integration in photovoltaic factories, and the SEMI A3 standard enables shop floor communication in PCB manufacturing.

SECS/GEM & GEM300 Integration with Fablink® - Your Benefits

- Reduced development costs

- Quick and easy implementation of SECS/GEM, GEM300, PV2, SEMI A3 and EDA (Interface A)

- Save time with pre-prepared SEMI documentation

- Implement your own follow-up projects quickly

- Training, requirements analysis, consulting, implementation, commissioning and support by experienced experts

- Support in implementing customer-specific requests and specifications

- More than 20,000 installations

- Continuous product development

- More than 25 years of expertise

Areas of Application for SEMI Standards in Equipment Manufacturing: Integration with Fablink®

Integrate your equipment conveniently, quickly and in compliance with complex SEMI standards. Make your mark on the innovative semiconductor market in all stages of automation by implementing your SECS/GEM, GEM300 and EDA interfaces.

Integrate your equipment in factories in the photovoltaic industry in accordance with the required SEMI PV02 standard.

Integrate your equipment with PCB manufacturing IT systems by using the SEMI A3 standard.

Features of the SECS/GEM & GEM300 Interface Fablink® at a Glance

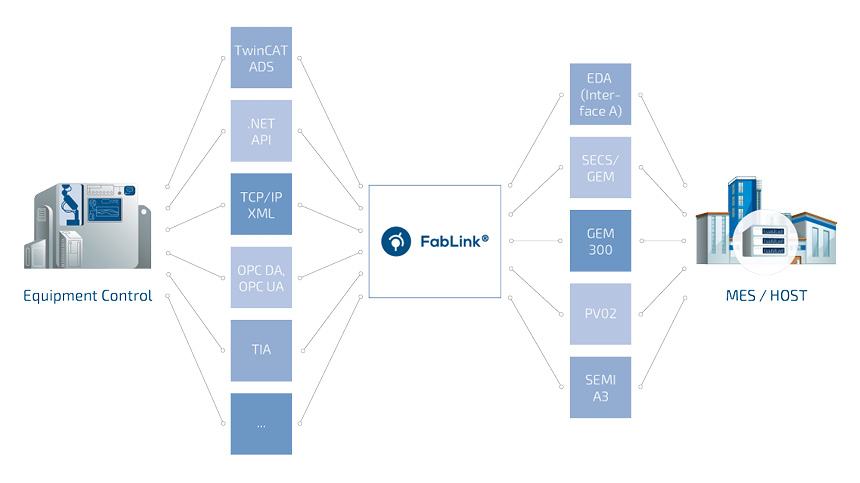

The SEMI-compliant system integration FabLink® builds on the equipment control and supports a wide range of protocols and control types. It opens up the world of SEMI-compliant integration for your machines with SECS/GEM, GEM300 and EDA (Interface A). In addition, we offer you a high degree of flexibility in the implementation of spooling, limits monitoring and terminal services functions.

With FabLink® Designer, we support the easy and clear configuration of the SECS/GEM interface for various equipment series. The pre-prepared interface documentation (GEM manual) in open file format enables custom adaptation so it is quickly ready for the factory operator.

Options for the Equipment Integration with FabLink®

Flexible FabLink® integration solution enables you to establish communication between machine and factory IT (e.g. host system) through various standards, interfaces and PLC systems.

| Interfaces, e.g.: | PLC, e.g.: |

|---|---|

|

|

SEMI Standard Compliance for the Semiconductor Industry

Dealing with the SEMI standards SECS/GEM, GEM300 and EDA is crucial for machine and equipment manufacturers in order to gain access to the semiconductor industry. SECS/GEM interfaces are also regarded as an industry-specific integration layer in photovoltaic, LED, flat screen and electronics production.

The extended GEM300-SEMI standards (E39, E40, E87, E90, E94 and E116) are specifically designed for fully automated factories. EDA is becoming increasingly important as a flexible and powerful interface for providing process data.

| SECS/GEM (200 mm) | GEM300 (300 mm) | EDA (Interface A) | Common Standards |

|---|---|---|---|

| Cybersecurity |

|---|

|

|

|

SEMI Standards for Photovoltaic Industry and Electronic Production

- Guide for PV Equipment Communication Interfaces (PVECI)

PV2 standard specifies a uniform IT interface for production equipment in the photovoltaic industry. The standard is largely based on the established framework of SECS/GEM norms and has been adapted to the specific needs of the industry. This promotes the use of powerful software systems in the area of factory control and management. SEMI PV2 enables factory IT systems such as manufacturing execution systems (MES) to access production machines and adjust their process parameters. In addition, the uniform interface provides, among other things, measurement, process and performance data for the machines.

- A3-0819 Specification for Printed Circuit Board Equipment Communication Interfaces (PCBECI)

In 2019, SEMI A3-0819 Specification for Printed Circuit Board Equipment Communication Interfaces (PCBECI) standard was published by SEMI. The SEMI A3 standard is an industry-specific adaptation of SECS/GEM standards to electronics manufacturing and describes a standard interface in PCB manufacturing for bidirectional communication between machine and host. In order to simplify data management, some SECS/GEM functionalities have been limited. SEMI A3-0819 therefore offers a robust, comprehensive and expandable standard for shop floor communication.

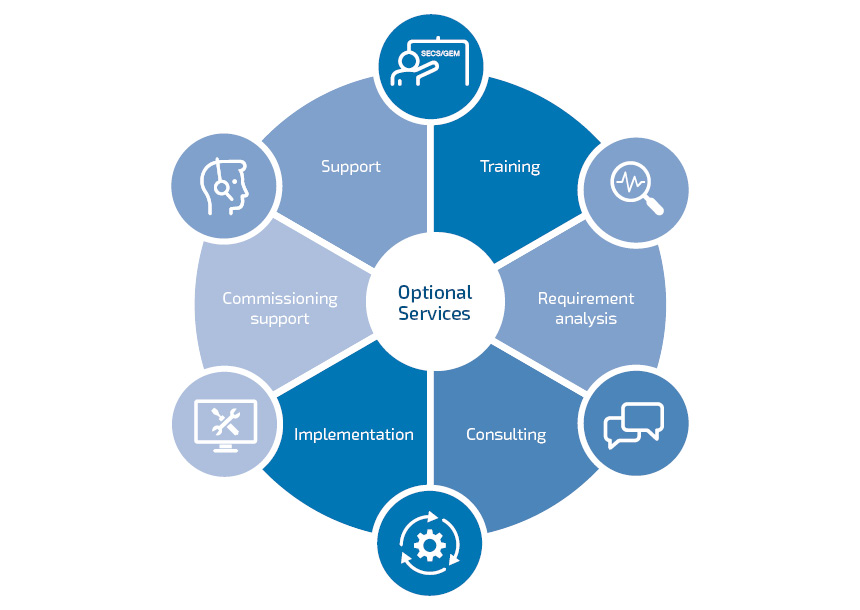

SECS/GEM, GEM300 and Fablink® Consulting Service for Your Equipment Integration

Thanks to FabLink®, you can connect your machines quickly and in accordance with the standards. Once you have successfully implemented the first project, all machine-specific configurations can be implemented quickly in subsequent projects without further assistance. However, since the implementation of an equipment interface according to the SEMI standard can be very complex and not very transparent, especially at the beginning, we provide you with support throughout the entire process of equipment integration. You can simply put together the right services you need from our extensive portfolio.

Training

Our introductory training courses and a follow-up project-specific workshop will provide you with the knowledge you need for your project. In order to implement your specific requirements independently in the future, we also offer comprehensive product training so that you can configure additional SEMI-compliant interfaces yourself.

Requirements analysis

We evaluate the specifications and compliance documents provided by your customers for you. Based on our experience, we analyze the relevant requirements on a machine-to-machine basis.

Consulting

In order to assist you during the project, we advise and support you in implementing the software.

Implementation

Depending on the requirements, you can implement your SECS/GEM interface yourself or let us do it for you.

Commissioning

On request, we will accompany you through to commissioning — either at your site or at your customer's.

Support

Even after the project has been completed, we will support you with future feature updates and with product or project support.

Get in Touch with Us

Local expertise for our customers in Asia

Our local partner in Taiwan has been at your side since 2025 as your expert contact for Asia. Benefit from short communication channels, direct support, and regional expertise.

Adirtek Co., Ltd

No. 101-1, Beizhong St.,North Dist., Tainan City

704033 Taiwan

Phone: +886-6-7003650

E-mail: sales.11@adirtek.com

Web: https://www.adirtek.com/

FAQs: FabLink® – Features, Benefits, Integration

FabLink® is software for vertical communication of production equipment and systems in semiconductor fabs. It supports common SEMI standards (e.g., SECS/GEM, GEM300, EDA) and enables standardized, scalable, and future-proof communication between equipment and higher-level systems such as an MES.

Yes, FabLink® can be connected to equipment via various interfaces (e.g., TCP/IP XML, .NET API, OPC DA, OPC UA, TwinCAT ADS, TIA). It does not matter whether the system control is a PLC control system, a PC-based control system, a proprietary development by the equipment manufacturer, third-party software, or a ToolCommander® control system from Kontron AIS.

FabLink® offers predictable budgets for fast implementation and commissioning. After the initial project implementation, FabLink® customers can configure additional systems themselves, saving time and money. At the same time, FabLink® Designer provides prepared SEMI documentation in an open file format to reduce the documentation effort.

FabLink® implements all relevant SEMI standards for SECS/GEM (E5, E30, E37) and GEM300 (E39, E40, E84, E87, E90, E94, E116), as well as EDA (Interface A) (E120, E125, E128, E132, E138, E145). FabLink also supports cross-platform standards (e.g., E172, E167, E148) and cybersecurity standards (E187, E188, E191). Additional standards can be implemented.

FabLink® collects equipment, process, and substrate data in real time and transfers it to higher-level systems in a structured manner in accordance with SEM and EDA standards. The data is used for monitoring, predictive maintenance, and quality assurance. The host controls the system, e.g., by specifying recipes.

Kontron AIS supports FabLink® customers throughout the entire project period with SECS/GEM, GEM300, and EDA training, requirements analysis, consulting, concrete implementation of the interface, commissioning, and, of course, support. With the Kontron AIS team of experts, who have more than 35 years of experience in the semiconductor industry, FabLink® customers have a strong and reliable partner at your side.

FAQs: FabLink® in der Praxis – Use Cases, Performance, Erfahrungen

FabLink® serves as a communication layer between machines, equipments and IT systems in the factory. In semiconductor fabs, it enables the standard-compliant connection of equipment via SECS/GEM, GEM300, or EDA. This enables equipment integration, full fab automation, and the use of process data for predictive maintenance and production optimization.

The typical use case: SEMI-compliant equipment connection using SECS/GEM, GEM300, and EDA. This enables you to enter the semiconductor industry quickly and securely with proven software, expert support, and planning reliability.

Yes, FabLink® is already being used successfully in many international semiconductor fabs. Currently, around 20,000 installations have been delivered. FabLink® is a mature and proven software product that is continuously maintained.

FabLink® provides access to real-time machine and process data (e.g., measurement data and cycle times) at a high frequency. These data can be integrated into data lakes or AI systems to identify patterns, quality potential, and wear patterns at an early stage.

FabLink® offers dual-stack capability and can operate SECS/GEM and EDA in parallel. However, it is also possible to use FabLink® as a stand-alone solution for EDA or SECS/GEM, or GEM300.