Integration of a control system for wafer measuring and inspection equipment

The semiconductor industry is booming. Chips are required all over the world for electronics production, which are processed on wafers in highly complex steps.

An important step is inspecting the wafers. Because these become more and more valuable right up to the end of the production cycle, constant monitoring of production is essential. This is where MueTec GmbH, a company that specializes in optical measurement and inspection of wafers, comes in.

Challenge

Challenge

- High inspection throughput of wafers at the end customer

- Different machine versions that need to be modular, flexible and configurable

- Fixed start of production at the end customer’s site

Solution

Solution

- ToolCommander® as a platform for equipment control

- FabLink® as an interface solution

- Advice and support during the entire project

Results

Results

- ToolCommander® as a worldwide standard tool for MueTec equipment

- New equipment shipped with Kontron AIS tool as standard component

- Ensuring quality and testing at the end customer

The partnership between machine builders and software developers

MueTec was looking for a partner with European reach for the control know-how of their equipment that can also implement requirements flexibly and promptly. As an established and experienced sparring partner in the semiconductor industry, Kontron AIS GmbH was the perfect choice. The good relations between semiconductor end customers in Silicon Saxony, for example, brought MueTec and Kontron AIS together based on word-of-mouth recommendation.

The areas of responsibility to be covered by Kontron AIS needed to include full-service project support, a specification phase, software development including roll-out and testing, and aftersales services. That’s why Kontron AIS was involved in the planning phase of the new wafer factory and the project team was looking forward to working with MueTec.

Da Vinci would be impressed by the machine

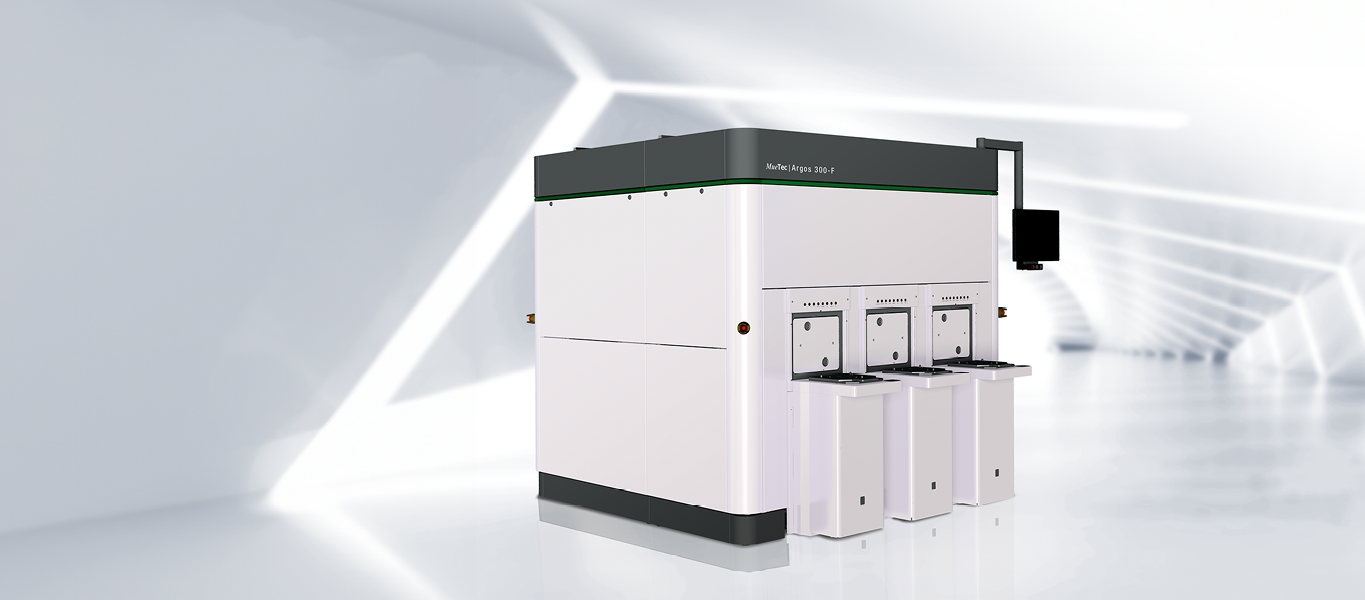

A high measurement density in wafer production also places high demands on process speed and safety. More wafers have to be processed and inspected in ever shorter cycle times. In order to meet these market requirements, MueTec has designed new types of equipment. The Argos and DaVinci series can measure and inspect wafers at a high frequency.

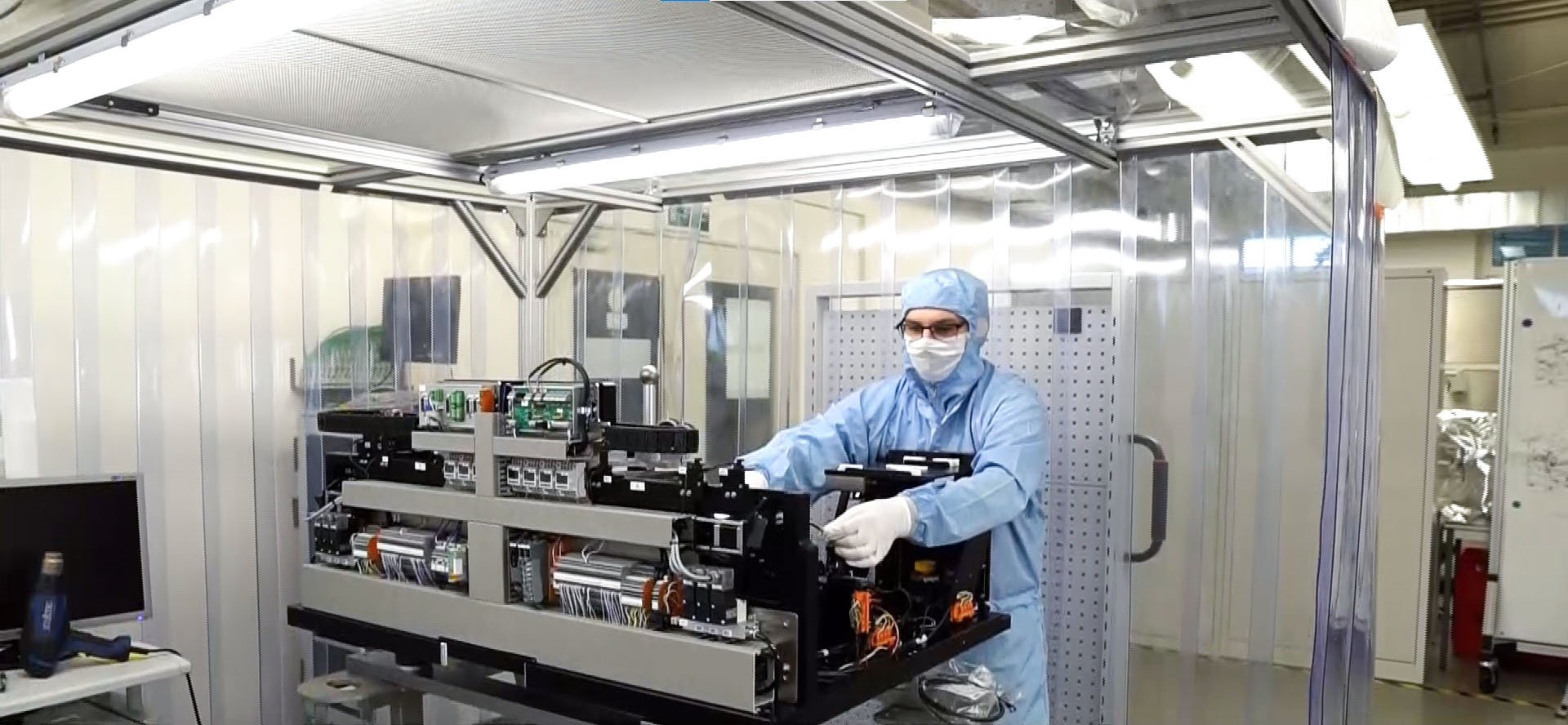

The role of Kontron AIS was to develop software that could keep pace with the high frequencies and execute and control internal machine processes. At the same time, the equipment series had to be provided with a host interface that met SEMI 300 mm standards.

Well-established processes in the project

At the start of the project, a specification for software development was prepared together with Kontron AIS based on MueTec's requirements. It specified that the solution uses the ToolCommander® software framework as control software and that the FabLink® connectivity solution is the interface to the host interface. All of this must comply with complex SEMI standards and meet the required GEM300 and SECS/GEM requirements. The equipment control system should also have an appealing visualization. This was also implemented using the ToolCommander® software framework and adapted to the customer’s requirements.

After approval of the joint specification, Kontron AIS could get started on the actual development work. During the project, MueTec always supported competently and reliably the development process as a customer and partner by providing the necessary information. Thanks to 30 years of experience in control systems development, Kontron AIS was able to quickly fulfill the specified work packages in close cooperation with MueTec and integrate them into the software.

A team consisting of three software developers, a tester and a software architect from Kontron AIS worked intensively on the project. Test automation was also used for quality assurance.

Finally, the software solution was put into operation with the equipment at MueTec.

The provided installer by Kontron AIS made installation and commissioning easier, so that MueTec only had to be supported remotely if necessary. Kontron AIS was always on-hand to answer questions during the final phase and the hardware integration was seamless via remote support.

| Outcome from the customer's perspective | Vorteile für den Kunden |

|---|---|

|

|

If you would like to find out more about the ToolCommander® system control, we look forward to hearing from you