Training for SECS/GEM, implementation of the interface between FabLink® and the equipment in C#

Royce Instruments is a global leader in designing precision assembly tools and high-accuracy, low-force bond test equipment for the semiconductor industry. Now V-TEK/Royce is able to provide GEM-compliant equipments to their customers. During a custom training and hands-on session, an Kontron AIS engineer explained the world of SECS/GEM to the customer and gave support during an initial implementation. As example we implemented FabLink ® on a Die Sorter during the training. After two weeks all GEM functionalities where implemented on the tool. After the detailed briefing, V-TEK/Royce was able to implement a full SECS/GEM interface with only a very small amount of additional support.

The implemented base is useable for any kind of new SECS/GEM interface. The big outcome is, that now all customers of V-TEK/Royce are able to buy equipments with full capacity of SECS/GEM based on FabLink® by Kontron AIS GmbH.

Goals

Goals

- SEMI-compliant SECS/GEM interface

- Explaining how to fulfill customers SECS/GEM expectations

Challenge

Challenge

- Implementing a customizable FabLink® integration

- First company-wide equipment with SECS/GEM

Result

Result

- Implementation of a solution for a Die Sorter and future tools

- State-of-the-art SECS/GEM interface

Generic SEMI-compliant SECS/GEM interface with FabLink® API

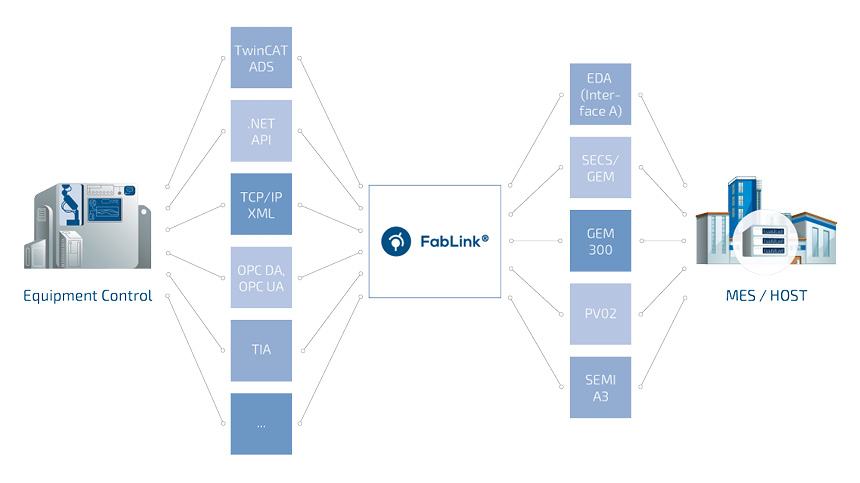

FabLink® helps our customers to be SEMI-compliant with little effort. Therefore, FabLink® takes care of the standard communication. It also offers many interfaces for an easy integration of the equipment software (C#, OPC, S7 communication, Profibus, TwinCAT ADS, CAN-Bus, Ethernet).

To configure the interface, Kontron AIS provides the FabLink® Designer, which helps the customer to document the interface with only very little effort.

In this project, we implemented the interface between FabLink ® and the tool in C#. We not only implemented the standard functionalities like sending events and parameter. We have also extended the interface by additonal remote commands, recipe management, terminal services and customized stream functions. All those functionalities were directly added to the existing C# solution of the equipment. In order to maintain a high reusability for upcoming projects, we have also shown how these functionalities can be implemented.

Kontron AIS not only supports device suppliers by implementing the SECS/GEM interface, but also assists semiconductor manufacturing companies with new tools to integrate them into their corporate systems. With this experience, we are able to show the expectations of semiconductor factories on SECS/GEM interfaces and ensure that the customers of new developed tools are pleased with the interface.

The training took place on-site at V-TEK and, like all of our trainings, it was customized to the costumers needs and requirements. During the intial SECS/GEM introduction software developers, management and salesforce learned the principles and ideas of a SEMI compliant interface. The additional hands-on session was realized agile to respond to open questions and to support an initial implementation.