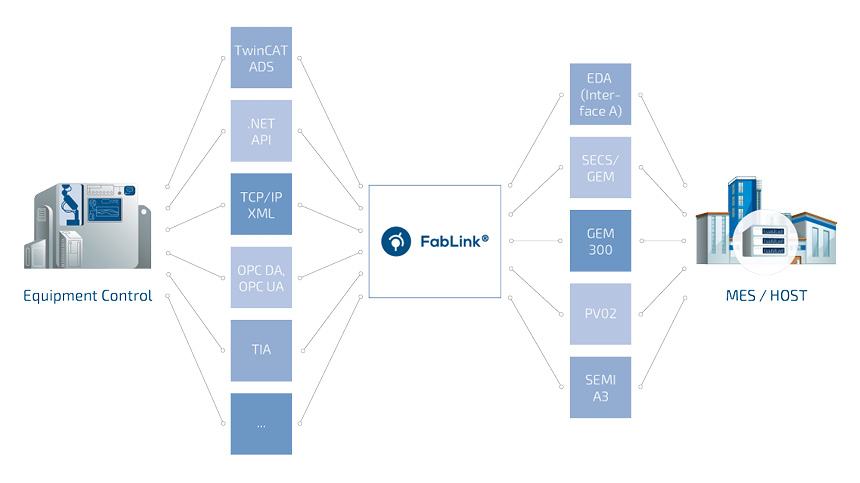

Due to a sharp increase in demand for standard interfaces for the semiconductor industry based on SECS/GEM, budatec launched a feasibility analysis for implementing the interface at their soldering furnaces. The decision was made to use FabLink® product from Kontron AIS, an established product with more than 10.000 references in 20 years. The FabLink® API for a .NET based control platform was a perfect technological fit for budatec‘s software architecture.

In addition to purely technical criteria, support from experienced experts was also a key criterion for deciding in favor of FabLink®. Support for evaluating extensive compliance documents provided by Kontron AIS and the expansion option to include an additional EDA SEMI compliant interface also provide security for the future.

Challenge

Challenge

- Implementing MES interface based on SECS/GEM

- Creating universal source code for various types of equipment

- Strict delivery time requirements

Solution

Solution

- Online SECS/GEM training and workshop

- Integration of the FabLink® API into own source code and build processes

- Using the template provided

Result

Result

- Independent implementation of SECS/GEM with FabLink® API

- Quick know-how transfer, 80 hours of total effort for implementation, documentation and testing

Strong solution for new business areas

Following short but detailed training on the SEMI standards and their usage, as well as a workshop on software development using the FabLink® API, it was a quick path to the successful implementation of the SECS/GEM interface. Both the maturity level of the API and the automated creation of the necessary GEM manual supported by FabLink ® help to keep development time and time-to-market very short. Add-ons to the machines can also be brought to market within a very short time.

The implementation of the SECS/GEM interface for the vacuum soldering furnaces offers budatec new opportunities in the fast-growing sectors of semiconductor, solar and electronics manufacturing.

Why SECS/GEM?

SECS/GEM is a collection of communication standards specified by Semiconductor Equipment and Materials International (SEMI), an international organization, together with industry. SECS is an abbreviation for SEMI Equipment Communication Standard. GEM stands for Generic Equipment Model and refers to the E30 SEMI connectivity standard. The protocol family defines a generic model for communication and control of production equipment.

In the complex manufacturing process, many process steps are carried out that can only be optimally completed and checked with the support of IT systems. SECS/GEM based networks enable remote control of production equipment and automated operation with the support of MES. Structured data collection also offers the opportunity to further improve quality and availability.

In SECS/GEM, functional models represent the material flow from loading to processing specifications, execution and unloading. For this to be done in a structured way, communication and various settings must be configured first. As a result reports on events, alarms and process values are available.

SECS/GEM provides a uniform interface for communication between automated machines and the host. Standardizing the interface between production equipment and the factory‘s IT system offers many advantages both for equipment integration and for machine manufacturers. Equipment become comparable and integration costs are reduced.

Standardized host interfaces are a prerequisite for being able to deliver machines to a semiconductor factory. FabLink® solves this requirement in a way that is flexible and can be implemented quickly, and therefore provides an add-on to the machine manufacturer’s portfolio.

If you would like to find out more about the SECS/GEM interface, we look forward to hearing from you.