Digital worker guidance directs operators at manual workstations through step-by-step assembly tasks and workflows – supported by clearly structured instructions, visual aids, and automated feedback. This standardizes your quality control at manual workstations and ensures seamless documentation of every step.

Whether it’s tracking material batches, measurement results, or process times — everything is transparently recorded and traceable. Especially in high-variant production environments, you significantly reduce errors and scrap, while speeding up and simplifying the onboarding of new employees.

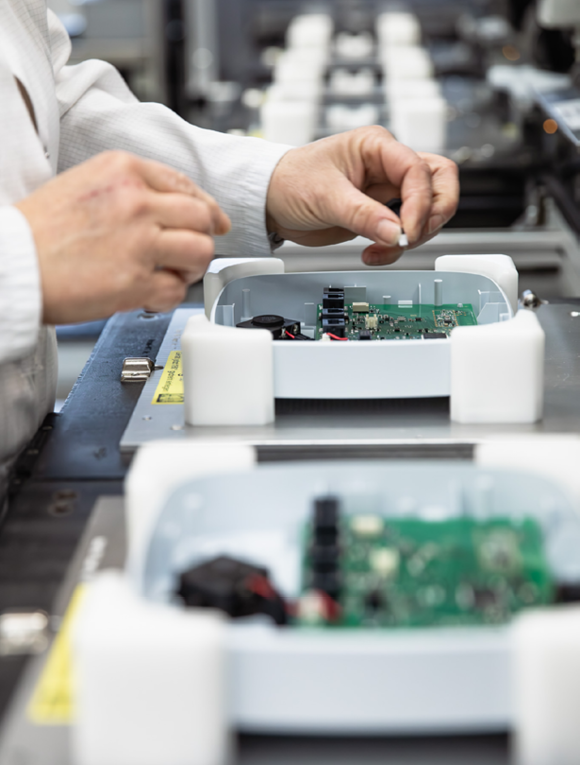

Thanks to intelligent integration of tools and measurement systems, operation becomes more intuitive, safer, and more comfortable for the operator. In electronics assembly, at testing stations, or in safety-critical areas, a worker assistance system excels by boosting efficiency, quality, and safety.

What Is Digital Worker Guidance?

Also known as a worker assistance system, digital worker guidance describes a software solution that guides operators at manual workstations through defined production steps in a simple and clear way.

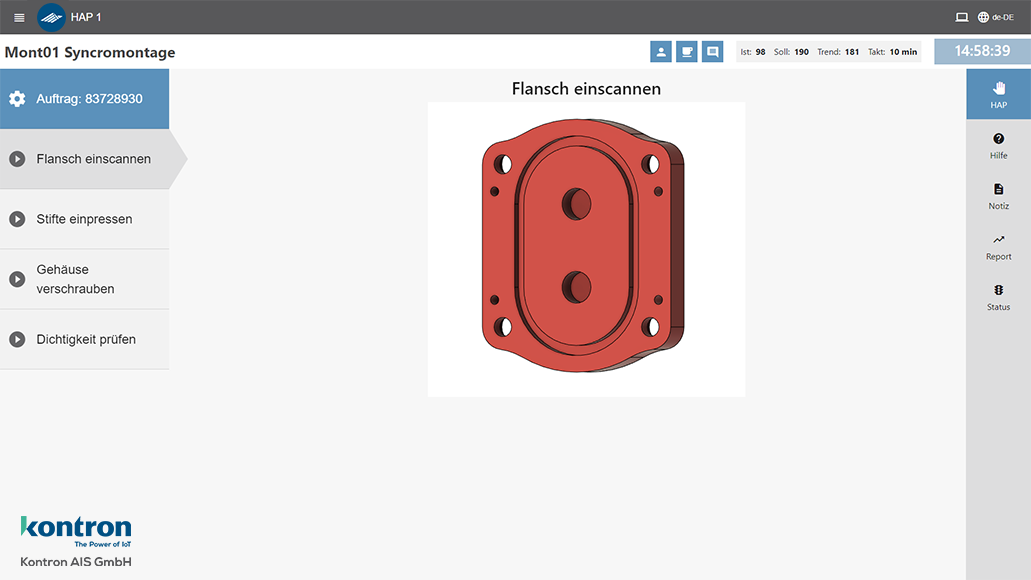

Instead of paper-based instructions, operators receive step-by-step directions directly on a screen. Information and guidance are provided at the right time, in a targeted manner. Visual content such as images, videos, or technical drawings supports precise execution – complemented by automatic feedback and checks.

At the same time, the software seamlessly logs all work steps including installed batches, measuring data, and processing times. This ensures transparent, traceable, and high-quality documentation for every task performed.

Applications Where Digital Worker Guidance Creates Real Value

Digital worker guidance has proven itself as a key factor for safer, efficient, and error-free assembly processes in many industries – especially where high product variety, short cycle times, and strict quality requirements coincide. Typical application areas include:

- Electronics manufacturing with high product variety: Worker assistance systems ensure process reliability, despite frequently changing product variants and varying teams in device manufacturing.

- Guidance at testing stations: Operators receive clear step-by-step instructions and can automatically record and document measurement results at test stations.

- Production areas with increased safety requirements: Complete documentation of every work step enhances safety and supports compliance with standards and relations.

- Rework stations on fully automated production lines: Digital worker guidance ensures that manual corrections are done efficiently, traceably, and error-free.

Technical Foundations of a Worker Assistance System

Worker assistance systems bring software intelligence and intuitive operation directly to manual workstations. This is made possible by the seamless interaction between the line controller or MES, workstation visualization, and integrated devices.

How it works:

- Central control via a line controller or MES:

The line controller or MES is the technical backbone, working in tandem with workstation visualization. These production control systems supply all relevant order data, work steps, parameters, and material and inspection requirements for the products. At the same time, the system automatically documents all process data to ensure traceability of every product. - Web-based visualization directly at the workstation:

Operators access digital work instructions via a web-based client at their workstation – supported by images, videos, or technical drawings for secure and error-free execution. - Integration of tools and measurement systems:

Data interface integration software connects tools and devices like presses, screwdrivers, or measuring instruments directly. External components such as scanners, pick-by-light, or camera systems flexibly complement the workstation to enable safe, fast, and error-free work.

Your Contacts for All Questions about Digital Worker Guidance

Our Software Solutions with Digital Worker Guidance

Frequently Asked Questions about Digital Worker Guidance

Digital worker guidance, also known as worker assistance systems, are software solutions that digitally support manual assembly processes at the workstation. Instead of paper-based instructions, operators are guided through step-by-step tasks directly on their screen, allowing every production step to be thoroughly traced and documented. This is especially important when producing different product variants.

You can use a wide range of formats: from photos, GIFs, and videos to PDFs and digital checklists. This allows you to create clear, understandable, and tailored instructions for your employees.

Yes, the line controller or MES is the core of your worker guidance system. All order, recipe, and process data are centrally managed here and automatically linked with the documented work steps at the workstation. This ensures seamless traceability as well as high transparency and quality in your production process.

Step-by-step instructions, automatic checks, and direct integration of tools ensure that all work steps for every product are executed correctly. This enables employees to immediately identify deviations, significantly reducing errors and scrap.

Absolutely. SMEs especially benefit from digital work instructions, for example, through simplified onboarding, secured processes despite variant-rich production, and fast, error-free documentation.