In modern manufacturing, the way production data is archived directly impacts quality, compliance, and competitiveness. Companies that systematically and permanently store product, process, and recipe data create transparency and fulfill legal traceability requirements – especially important during audits, customer complaints, or process optimizations.

The production database of a line controller is optimized for real-time control and monitoring of ongoing processes. However, long-term archiving large volumes of production data requires a specialized storage system. This ensures that current control data remains high-performing, while historical data are stored in a structured and compliant manner. As a result, production data remains accessible for years, supporting quick root-cause analysis and continuous quality improvement.

What is an Archiving System for Line Controllers?

An archiving system extends a line controller like FabEagle®LC with a central component that permanently records, stores, and makes historical production data on products, processes, and recipes accessible. It separates current data from long-term data that must remain available for many years, enabling efficient and audit-proof archiving.

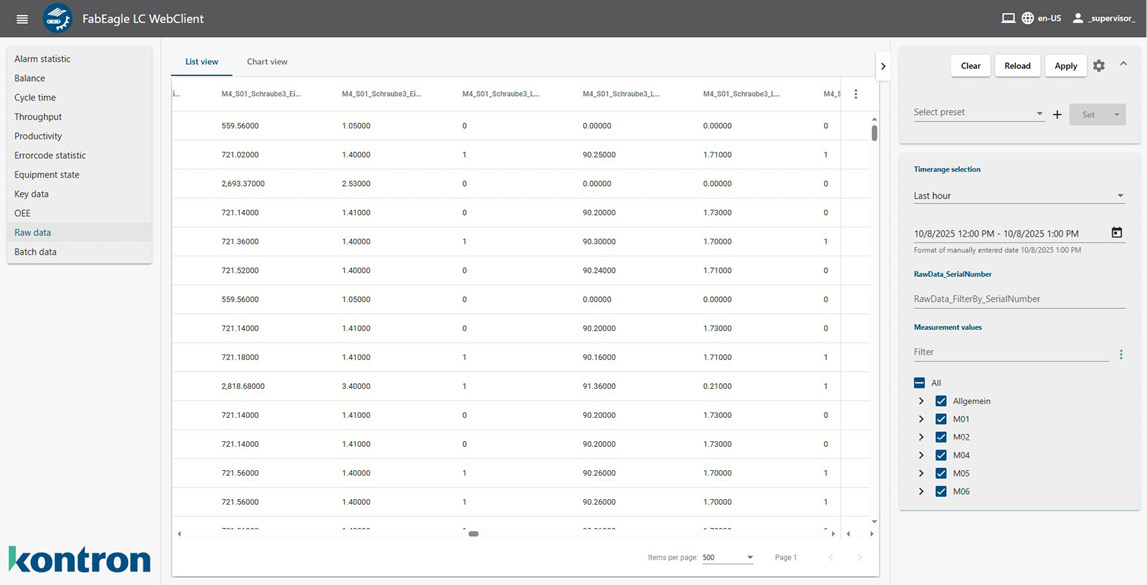

Archiving systems typically consist of one or more databases and software that automatically export production and product data from the productive database. Data are stored securely and in a structured manner, ensuring complete data availability even after several years. Through an integrated web client, users can conveniently search and analyze archived data, without needing advanced IT expertise.

Especially in industries with strict traceability requirements, such as automotive or pharmaceuticals, archiving systems are indispensable. In automotive manufacturing, for example, they document safety-critical components like airbags or braking systems, while in the pharmaceutical industry they ensure GMP-compliant recipe documentation.

Benefits of an Archiving System

An archiving system enables safety-critical industries to fulfill regulatory documentation and traceability requirements for product quality and integrity. All product, process, and recipe data are automatically and completely captured, ensuring transparency for customers and authorities and enabling full traceability down to batch or individual component level.

When complaints occur, archived long-term data provide the decisive information: which materials, parameters, and recipes were used. Manufacturing processes can be reconstructed in detail to identify errors quickly. In case of liability or warranty claims, archived data also serve as legal evidence.

Long-term data analysis reveals trends that remain hidden in daily operations. Using historical production data, data-driven quality management identifies optimization potential in machines and recipes, thereby reducing scrap. This enables process and product quality to be improved step by step.

By offloading data storage to an external archiving system, the productive database of the line controller remains lean and responsive. Time-critical control and monitoring tasks run without delays, while analyses are processed efficiently within the archiving system.

Your Contacts for Software Solutions with Archiving System

Our Software Solutions with Digital Worker Guidance

FAQs about Archiving Product, Process, and Recipe Data

Yes, the database is accessible via defined interfaces within your production IT environment. On request, we can configure interfaces to connect your analytics tools like Power BI directly for structured data evaluation.

Archiving systems require regular maintenance. Our team supports you with this. SQL database updates are performed as part of an ongoing maintenance and support contract. Upon request, we also handle backup validation and database maintenance to ensure long-term stability and security of your solution.

Yes, the archiving system integrates seamlessly with existing MS SQL servers. Alternatively, we can assist you in setting up a new archive infrastructure tailored to your IT policies and security requirements.

Historians record time series data such as temperature, pressure, or output from machines and processes. While they are well-suited for trend analysis, they do not link product and recipe data. For audit or product contexts such as recipe approvals or complete traceability, archiving systems are the better choice.

Product data, process values, recipes, and reports can all be stored. Retention periods are defined by legal regulations or internal policies. Retention rules control how long data are stored and when they are exported or deleted within the archiving system.

Every change to recipe parameters or batches is versioned and documented by the archiving system. Exported data provides verifiable proof for internal audits and customer requirements.

Machines, controllers, MES, and ERP systems are connected through standardized interfaces to the archiving system. Data are transferred based on defined rules, consolidated, and made available for analysis, while complying with existing security, backup, and monitoring concepts.