Machine connection with FabEagle®Connect

As a developer and manufacturer of infrared sensors, InfraTec uses the latest manufacturing technologies and software tools from the area of digitalization to ensure continuous innovation and high quality. The production of infrared sensors requires highly precise, multi-stage processes that document data-supported process values and test results.

“The integration was quick and we were provided with immediate support. The tool could be used specifically for our requirements.”

Jörg Weih, IT project manager, InfraTec GmbH

Challenge

Challenge

- Machinery with OPC UA server without standardized data structure

- Customer software without interface to machine control

Solution

Solution

- Specification of data exchange with machine manufacturer and operator

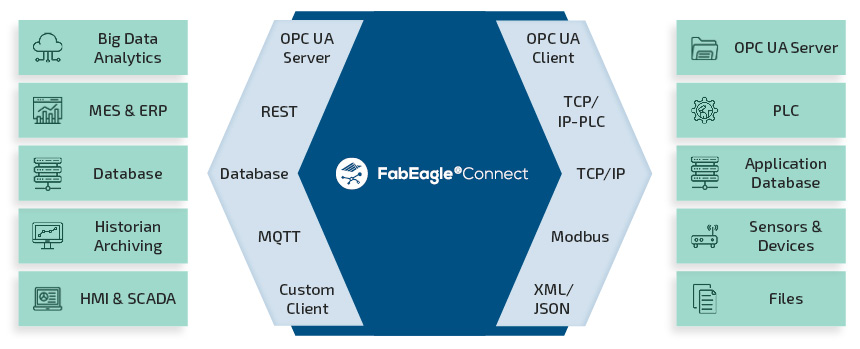

- FabEagle®Connect as a converter from OPC UA to TCP/IP (XML)

Result

Result

- Reliable, scalable and highperformance data transmission

- Data collection without operator intervention

With FabEagle®Connect integration software, Kontron AIS enabled interface integration and data conversion between a coating machine and customer software for data processing. The data are provided by the machine OPC UA server and are captured by FabEagle®Connect to be converted and transferred via TCP/IP in XML format to the customer software.

Despite the OPC UA standard for machine control, interface integration is usually not possible without specification of the data exchange between the machine and the customer software. In addition to the FabEagle®Connect integration solution, this also included the specification, clarification with the machine manufacturer, testing and commissioning of the solution to implement the integration project. The maintenance-free solution is managed by in-house IT and runs efficiently on a machine computer.

Your contact person