Integration of new components into the existing control system

As a disposal center for construction and commercial waste and a provider of waste recycling, AMAND Umwelttechnik makes a very significant contribution to protecting the environment. Between 50,000 and 85,000 tons of secondary fuel are produced annually at the Dresden site and delivered to the power and cement industries.

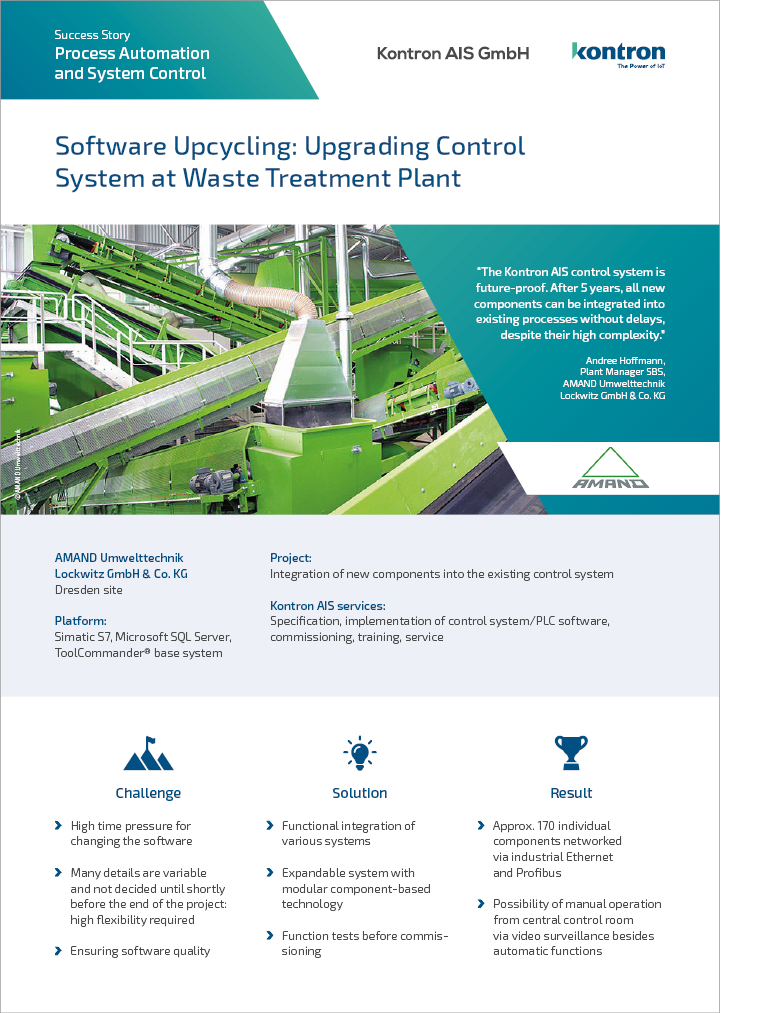

The process required for waste treatment is complex, with different processing stages such as crushing, screening and metal removal. To automate this complex process, AMAND chose a Kontron AIS control system 15 years ago.

Parts of the plant was renewed in 2020. Kontron AIS then upgraded the control system and integrated new machines into the existing control concept. One of the challenges was the very tight time frame.

“The Kontron AIS control system is future-proof. After 5 years, all new components can be integrated into existing processes without delays, despite their high complexity.” Andree Hoffmann, Plant Manager SBS, AMAND Umwelttechnik Lockwitz GmbH & Co. KG

Challenge

Challenge

- High time pressure for changing the software

- Many details are variable and not decided until shortly before the end of the project: high flexibility required

- Ensuring software quality

Solution

Solution

- Functional integration of various systems

- Expandable system with modular component-based technology

- Function tests before commissioning

Result

Result

- Approx. 170 individual components networked via industrial Ethernet and Profibus

- Possibility of manual operation from central control room via video surveillance besides automatic functions

Reduce complexity with visualization and data analysis

AMAND has been successfully operating a Kontron AIS control system for the production of secondary fuels for over 15 years, consisting of a PLC with a control panel and a line controller. A total of over 170 components are connected to the highly complex system. This includes conveyor belts, presses, scalpers, screening drums, crushers, fine grain wind stratifier and a several other processing steps.

The Kontron AIS solution provides the plant operators with a wide range of functions. These include management, control and evaluation of data, as well as reporting. The operator can access plant overviews, manual control dialogs, message archives and statistical evaluations for support in their everyday work. In addition, the user interface allows plant operators to change programs that are running during automatic operation and eliminate malfunctions, so they can react quickly to any errors that occur.

Quick integration of new components thanks to the modular design of the control system

Having renewed around 20 % of the plant components in 2020, the new components had to be integrated into the control system process to continue to ensure the automated process for the production of secondary fuels. This required adjustments throughout the entire system, from interfaces and process logic to visualization and data evaluation.

In order to meet the two weeks required for commissioning, it was necessary to have a good preparation phase to coordinate every detail. AMAND benefited from the fact that the Kontron AIS system was designed to be modular and expandable, and that in addition to software technology, the Kontron AIS team had a sound understanding of the process. This enabled commissioning to be carried out successfully following extensive signal tests, functional tests of all individual components and testing of the automatic functions. It was possible to react quickly and flexibly to delays caused during plant construction.

Following completion of the upgrade, the system continues to run reliably in providing industry with a supply of resource-saving energy.

If you would like to find out more about the ToolCommander® system control, we look forward to hearing from you