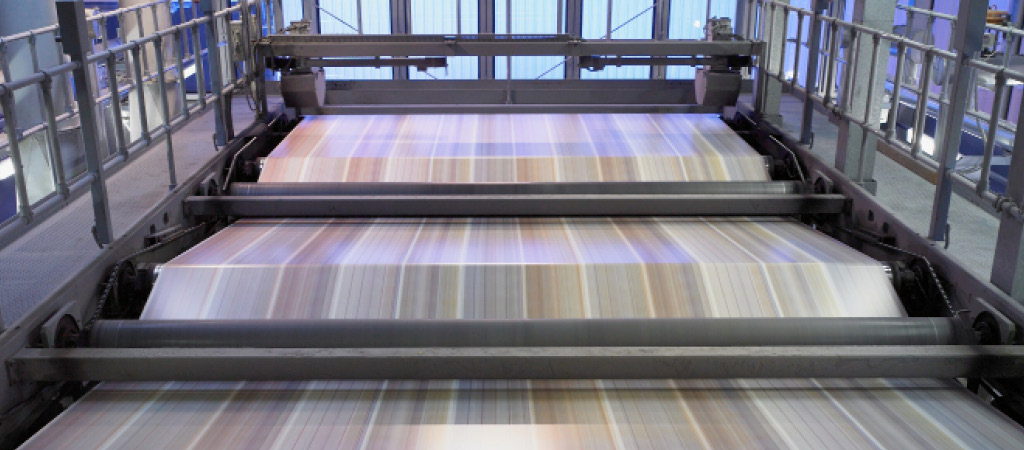

High-quality production systems are running several years. Despite a flawless function there are occasionally upcoming problems through the years – e. g. discontinuation of operating systems and control components by the manufacturer. At some point, the facility operability can no longer be safely ensured.

The renewal of the line control technology in the production of intaglio printing/rotation at Prinovis Dresden ensures, that the facilities are still running stable and technical support ist available. Furthermore the modernization of the production control system also opens up many new functions for the plant.

„Kontron AIS GmbH is a reliable partner convincing by innovation and stability. A premium provider of high-performance line controller solutions.” Thomas Schirmer, Project Manager, Prinovis GmbH & Co. KG (Dresden)

Goals

Goals

Long-term availability of the line control systems in the areas of intaglio printing/ rotation

Challenge

Challenge

- Preparative tests in the factory – parallel to the ongoing production

- Seamless upgrade without interuption of production

Ergebnis

Ergebnis

- Increasing process quality

- Consistent software architecture of line control systems for the intaglio printing/rotation at the customers plant

Details about the project

Along with the modernization of the production control system, a high performance software architecture was put in place. Hence the interfaces of the transport devices in cell controller applications are relocated. As a result an interface standardization and a separation of duties between machine and system integration, visualization, operation and logic as well as data storage was achieved.

The server systems are operated on a virtual VMware platform. This is the base for an improved maintainability and availability. Graphical representation of line controller dialogues and job management within the operator application is realized with WPF.

Operators have responded completely positive to the new look and feel of the operating application, which they see as a distinct improvement in order processing.