Introduction of customer portal for the project management of mixing and dosing systems

The company RAMPF Production Systems is a leading international supplier of customized dispensing systems and supplies industrial customers with its innovative systems worldwide. Effective, location-independent customer communication and long-term customer satisfaction are of great importance here. To further ensure this, the existing solution for customer communication was supposed to be replaced by a modern customer portal.

Data security, efficient project communication and the potential for agile development to enable innovations for global customer service were central aspects in the selection of the appropriate solution. With the cloud-based customer portal “Project Cockpit“, Kontron AIS has developed an intuitive, tailor-made customer solution and created a significant competitive advantage for RAMPF.

Challenge

Challenge

- A multitude of customer-specific adaptations (branding)

- Structuring and establishing project hierarchies

- Seamless migration of the existing portal solution

Solution

Solution

- Customer portal for communication and documentation of projects

- Automated document integration via embedded interface (API)

- 99 % of project communication via cloud solution

- Cross-functional time saving and increased efficiency

- Improved customer service

What the CEO of RAMPF says about the cloud-based customer portal

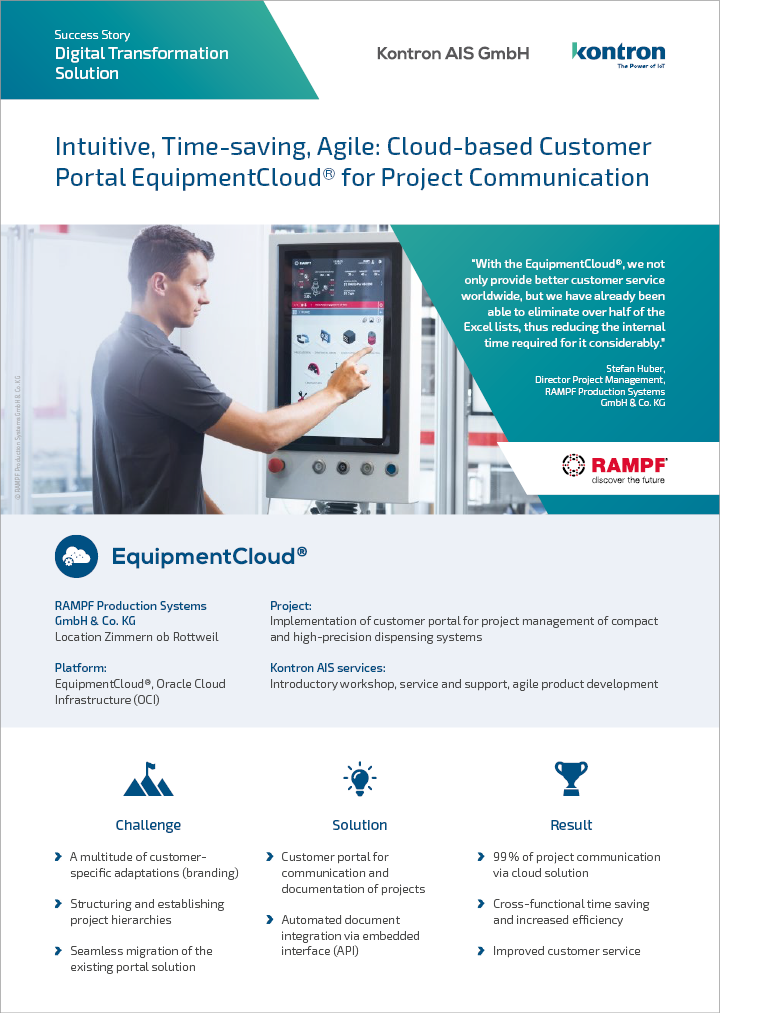

“With the EquipmentCloud®, we not only provide better customer service worldwide, but we have already been able to eliminate over half of the Excel lists, thus reducing the internal time required for it considerably.”

Increasing customer satisfaction while streamlining internal processes

The challenging aspects of the project were twofold. On the one hand, the focus was on the customer and his needs. How can communication be better organized in the client‘s direction? How can he contact RAMPF at any time and from anywhere? How can customer service be expanded to ensure high customer satisfaction in the long term?

On the other hand, the new solution was supposed to optimize internal processes significantly: channel relevant and up-to-date project and equipment information to the customer, obtain customer feedback, and streamline internal workflows. The following functional areas were involved – from documentation and internal administration to project management and customer service – and were given access to processes, documentation, and master data in a central place.

To solve these problems, RAMPF opted for the EquipmentCloud® digital transformation solution from Kontron AIS. The cloud-based customer platform was intended to sustainably improve customer communication and serve as an interface for project management. The interactive applications of the platform, which were tailored to mechanical engineering and allowed an immediate start, were a crucial part of reaching that goal.

Complete customization and integration of all project documentation

When setting up “Project Cockpit“, it was very important to RAMPF to create a high level of recognition with the customer. Kontron AIS developed a variety of new branding functionalities for the EquipmentCloud®, including individualization through titles, images and logos, color tones, fonts, a self-registration and management function of new users, privacy policies, e-mail templates, as well as feedback and domain redirection. Clients could register themselves independently at the new customer portal and RAMPF employees allocated the users to the respective projects and hierarchies.

The handling of the customer portal had to be intuitive for both colleagues and customers and should be designed according to familiar working methods. This posed a challenge, as the role concept and the visibilities are based on the hierarchy structure and represent the central navigation of the solution. For this purpose, the rights management was expanded step-by-step and all project participants were involved from the beginning in order to understand who needs access to which information at what time and to which extent.

Since RAMPF wanted to transfer both new projects and existing projects to the customer portal and already had extensive documentation in the form of Excel forms and documents in countless formats with exact assignment to the customer on drives and the existing portal solution, migration and data integration represented further important milestones.

This was realized by means of available interfaces (Restful APIs) for automated and rolling data integration and the extension of the documentation module (eDocs) to support HTML files. In addition, important performance improvements were implemented through system updates of the underlying Oracle Cloud Infrastructure (OCI).

EquipmentCloud® – the all-rounder for customer and project communication

Through document management (eDocs), master data management (EquipmentHub) including journal and the OpenIssues module for the orchestration of open tasks, a great number of existing Excel forms have already been replaced and bundled in one place – the customer portal. This has improved communication with end customers substantially. The availability of information and important documentation was now possible at any time and worldwide.

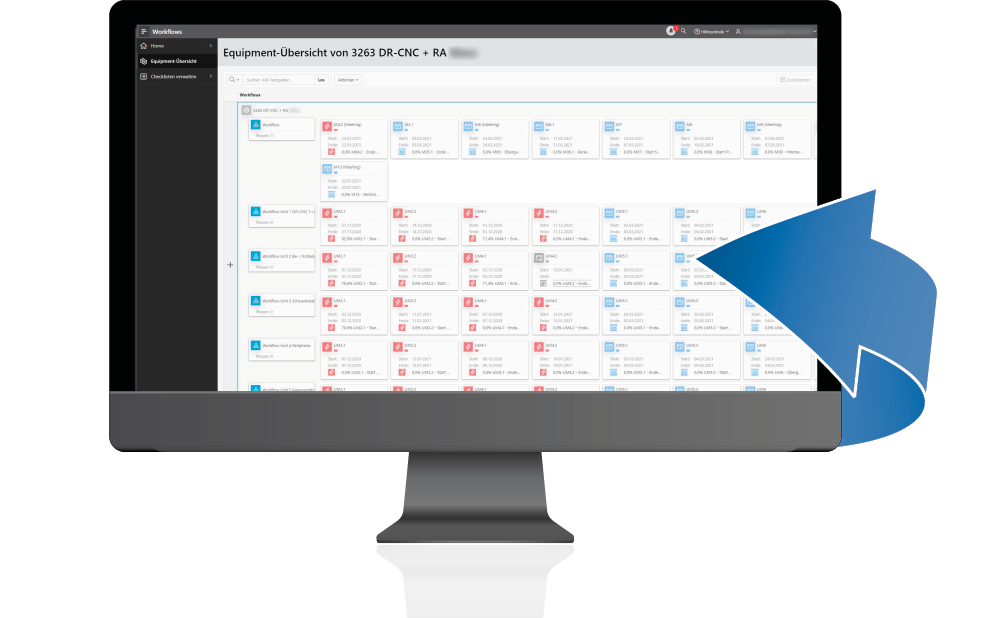

Thanks to the Workflows module, which can be used for process optimization and milestone planning of projects with integrated digital checklists, all internal and external participants always stay up to date, tasks can be assigned and processed step by step.

A dashboard with dynamic widgets additionally improves the usability of the customer portal. Changes to documents, open tasks or direct links to master data and upcoming deadlines of the more than 1,000 integrated instances are visible immediately. Automatic notifications via e-mail by subscribing or assigning responsible persons, enable project managers (commissioning engineers or technicians) to always stay up to date and take action if needed.

Stefan Huber, Head of Project Management, and initiator of the “Project Cockpit“ at RAMPF, considers the Equipment Cloud® to be an all-round tool and has set himself the medium-term goal of handling 99 % of project communication via the cloud solution. The high level of acceptance among colleagues due to the step-by-step rollout and testing of new applications was given from the very beginning. The entire team benefits from crossfunctional time saving and increased efficiency thanks to the customer portal. Additionally, the web-based customer portal provides end customers a central point of contact that can be accessed flexibly and barrier-free via various mobile devices. With Kontron AIS as partner and the digital transformation solution EquipmentCloud® as a platform, the basis for digital customer service has thus been created.

By implementing EquipmentCloud®, RAMPF was able to achieve the following results

Documents and data are made available seamlessly via interfaces (APIs)

With modules such as eDocs and EquipmentHub, all relevant information is bundled in one place.

Digital checklists and milestone planning ensure efficient workflows.

Tools specially developed for mechanical engineering enable intuitive operation and quick training.

More than half of the Excel lists were eliminated, resulting in a significant reduction in internal time.

99% of project communication now takes place via the cloud solution, which considerably simplifies the exchange of information.

The portal makes it possible to communicate at any time and from anywhere, which significantly increases customer satisfaction.