A machine is running on the shop floor and at first glance, you wouldn't guess its origin. Originally designed for the semiconductor industry, it now manufactures high-precision sensors. Its native language? SECS/GEM – a well-established standard for equipment integration in the semiconductor world. The challenge: the rest of the factory's IT systems don’t understand that language.

From sensor manufacturing to electronics production and microsystems technology, more and more companies are adopting the established and proven SECS/GEM standard to connect complex machines to traditional production and IT systems such as MES, ERP, or databases. In doing so, SECS/GEM meets widely used industrial interfaces like OPC UA, MQTT, or REST APIs. This blog article shows you how to bridge the communication gap between SECS/GEM-based machines and the IT architecture of classic factory environments.

What Makes SECS/GEM Different?

Like other interface protocols, SECS/GEM aims to enable flexible and standardized machine integration. But it takes a different approach. More than just a bidirectional interface, SECS/GEM provides a clearly defined communication model between host and equipment. The host – typically an MES – monitors and controls the machine, while the machine reports back data in the form of variables, states, or events.

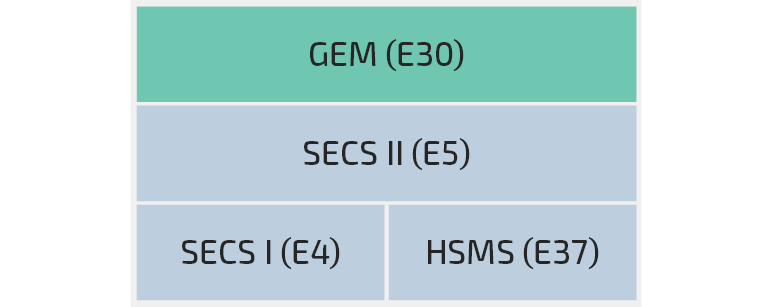

The SEMI E30 GEM standard defines the overall communication logic, including structured state models such as for communication establishment (Communication State Model) and for equipment status (Control State Model). This ensures consistent, transparent data exchange – a major advantage in strongly regulated manufacturing environments where traceability and process reliability are non-negotiable.

Beneath that, SEMI E5 SECS-II defines the structure of message content using streams (S1, S2, …) and functions (F1, F2, …) that request or provide predefined data. This allows highly precise control and monitoring information to be transmitted, such as recipe parameters, alarm states, or product data.

Compared to standards like OPC UA, which rely heavily on object models and generic structures, SECS/GEM additionally offers more clearly defined communication patterns and a standardized communication logic. This makes it easier to model machine behavior with precision – a key benefit in highly automated, variant-rich production environments that demand traceability.

Real-Time Monitoring Beyond the Semiconductor Floor – Powered by FabEagle®Connect

When SECS/GEM-based machines are used outside of their original semiconductor setting, they often face compatibility issues with existing IT systems, making translations necessary. That’s where FabEagle®Connect steps in. This integration software reliably translates between SECS/GEM-based machines and commonly used IT systems. Machine data – such as alarms, events, or state changes – flows directly and in real time into databases, MES, ERP, or cloud solutions.

A real-world example: In sensor manufacturing, where product variation is high, recipe parameters such as temperature, gas flow, or process time need to be transmitted quickly and reliably to the machines. With FabEagle®Connect, these recipes are sent directly from the MES. The SECS/GEM interface ensures that each machine receives the correct recipe version – reducing manual input, minimizing errors, and increasing process reliability.

FabLink®: When Everything Runs on SEMI Standards

FabEagle®Connect is ideal for mixed IT environments, acting as a universal translator between SECS/GEM-based machines and traditional IT systems. To integrate equipment into industry-specific MES platforms in the semiconductor industry, we offer our FabLink® interface integration solution, which is fully based on SEMI standards.

FabLink® supports full equipment integration based on SECS/GEM, GEM300, and EDA (Equipment Data Acquisition). This SEMI-compliant interface solution meets all the requirements for equipment that needs to be integrated vertically in fully automated semiconductor fabs.

SECS/GEM – Evolving from Semiconductor Standard to Cross-Industry Enabler

SECS/GEM may have started in the semiconductor sector, but it’s quickly proving its value across a wide range of high-tech industries. With its precise control and communication logic, it’s a perfect fit for highly automated production processes. Tools like FabEagle®Connect make it possible to integrate SECS/GEM-based machines into conventional IT systems – reliably, flexibly, and without deep programming expertise.

For applications fully committed to SEMI standards, FabLink® offers a powerful, high-performance integration solution supporting SECS/GEM, GEM300, EDA, and industry-specific cybersecurity requirements.

As an experienced integration partner, we support you from requirements specification to implementation and commissioning. Together, we drive the digital transformation of manufacturing across industries.

Interested in a SECS/GEM Integration Solution Beyond Semiconductor? I am Happy to Support You!