IoT Starter Pack and IoT Hub for Digital Service Portfolio for Grinding Machines

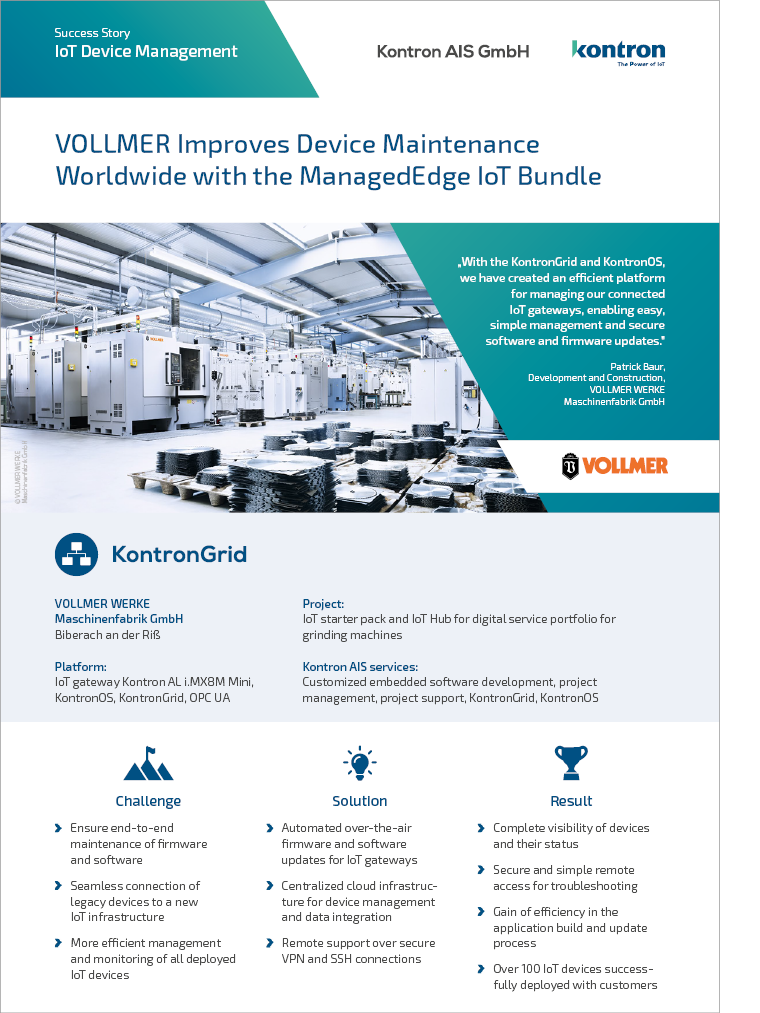

VOLLMER WERKE Maschinenfabrik GmbH, a leading manufacturer of grinding, eroding, laser and processing machines for wood and metal processing, was faced with the challenge of implementing centralized and efficient management of its globally installed IoT devices. The requirements included continuous maintenance without manual intervention, secure remote access for support, and regular provision of software and firmware updates.

These complex requirements were solved through close collaboration between Kontron Electronics, Kontron Technologies and Kontron AIS. As a long-standing partner, Kontron Electronics has developed numerous hardware and software solutions for VOLLMER. For this project, VOLLMER relied for the first time on the ManagedEdge IoT bundle, consisting of the KontronGrid IoT device management solution and the secure, hardened Linux®-based KontronOS operating system for the Kontron IoT gateway AL i.MX8M Mini. This solution enabled VOLLMER to move from a custom hardware and software architecture to a flexible and efficient off-the-shelf solution. As a result, VOLLMER benefits from reduced development and project implementation costs, faster time-to-market and a future-proof infrastructure for centrally managing and updating its global machine fleet.

Challenge

Challenge

- Ensure end-to-end maintenance of firmware and software

- Seamless connection of legacy devices to a new IoT infrastructure

- More efficient management and monitoring of all deployed IoT devices

Solution

Solution

- Automated over-the-air firmware and software updates for IoT gateways

- Centralized cloud infrastructure for device management and data integration

- Remote support over secure VPN and SSH connections

Result

Result

- Complete visibility of devices and their status

- Secure and simple remote access for troubleshooting

- Gain of efficiency in the application build and update process

- Over 100 IoT devices successfully deployed with customers

Why an IoT device management solution was crucial

In 1909, Heinrich Vollmer designed the first sharpening and filing machine for saws. His vision: maximum sharpness for cutting tools and saw blades. VOLLMER has been fulfilling this vision for over 100 years and has developed into a global technology leader. The machines for grinding, eroding, laser as well as machines for processing wood and metal are in demand internationally – from North America to Asia.

With the company's global presence and increasing number of machines installed, the need for centralized, connected management and maintenance of embedded devices has grown. An IoT device management solution promised to efficiently solve the challenges of global device management: Through centralized monitoring and management, it was possible to minimize downtime of edge devices, perform regular software and firmware updates, and ensure a high quality of service. For VOLLMER, it was critical to find a solution that would enable them to always keep their IoT devices up to date, while providing efficient and flexible technical support – without manual intervention on site.

Long-term partnership as the basis for innovation

VOLLMER and Kontron Electronics have enjoyed a close partnership for over 30 years. During this time, numerous customer-specific hardware and software solutions have been implemented, including the development of control systems, operating units, I/O modules and PCs for the VOLLMER machine portfolio. VOLLMER was also able to rely on Kontron's proven expertise in this project. At the beginning of the IT activities, the focus was on a customer-specific design with an i.MX6 platform, for which Kontron developed a customized software solution.

However, as the project progressed, the need for more computing power and therefore a new generation of hardware became clear. Together with Kontron, various options were evaluated, which ultimately led to a switch to a standard solution: the AL i.MX8M Mini hardware in combination with the KontronOS operating system. This switch to standard products made it possible to fully meet VOLLMER's specific requirements thanks to the configurable and expandable approach of KontronOS.

Smooth operation despite Kontron's renewal of the existing IoT infrastructure

When it came to renewing the IoT infrastructure, VOLLMER needed a solution that would ensure that the IoT devices already installed would continue to operate smoothly without the need for a physical upgrade. Kontron took on this task and ensured a seamless update service for firmware and software. An important component was the provision of a suitable Linux® based operating system that was compatible with both old and new devices. Equally important was the use of the existing CA root certificate to ensure secure communication between the machines and the cloud.

The solution: IoT device management with KontronGrid and secure operating system KontronOS

To solve the challenges of global machine management, VOLLMER selected the KontronGrid IoT device management solution and the secure Linux®-based KontronOS operating system for edge devices. The bundle enables centralized monitoring and management of all edge devices installed in machines worldwide, so that firmware and application updates can be coordinated and reliably distributed to the devices via the cloud – without manual intervention on site. This ensures that IoT gateways are always up to date and that failures are avoided at an early stage. KontronOS ensures the operation of applications such as real-time data acquisition from machines on the IoT device and provides backup and fallback security in case of failures thanks to two redundant partitions. The customer can independently initiate the updates provided by VOLLMER with a single click.

A particular advantage of the bundle is the option of remote maintenance. With the customer's prior consent, the support team can now access the machines remotely without having to be physically present. The device must simply be connected to the Internet where support is provided directly through the IoT connection. This feature has significantly increased the efficiency of support at VOLLMER, shortening response times and raising service quality to a new level.

Benefits of Docker Compose and efficient update management

The IoT Hub is a central element of VOLLMER's digital service portfolio and provides an intuitive platform for easy navigation to applications on IoT devices. Instead of manually entering IPs and ports, it provides direct access to relevant applications and data via tiles.

Customers can use the IoT Hub to access a dashboard that provides an overview of the equipment with status, current job and machine messages, as well as design their own IoT processes with Node Red. An additional notification service provides information about irregularities or status changes on machines. Customers can also view licensing information for each product and access IoT gateway documentation. The IoT Hub also simplifies access to firmware and software updates, which can be delivered via IoT Device Management and installed securely and independently on IoT devices. On the other hand, network interfaces and firewall zones can be configured via the KontronOS web interface. This greatly simplifies the work of machine operators and enables efficient use of equipment data.

Future-proof through digital connectivity

With the successful implementation of KontronGrid and KontronOS on the renewed IoT infrastructure, VOLLMER has created a solid foundation for the digital future. The centralized IoT device management solution and secure operating system not only enable efficient management and maintenance of the global device fleet but also lay the foundation for meeting the security requirements of NIS-2 and CRA. Secure remote maintenance and continuous access to machine data will enable VOLLMER to respond even more specifically to customer requirements and develop new digital services in the future.