FabEagle®MES for measurement and classification platform

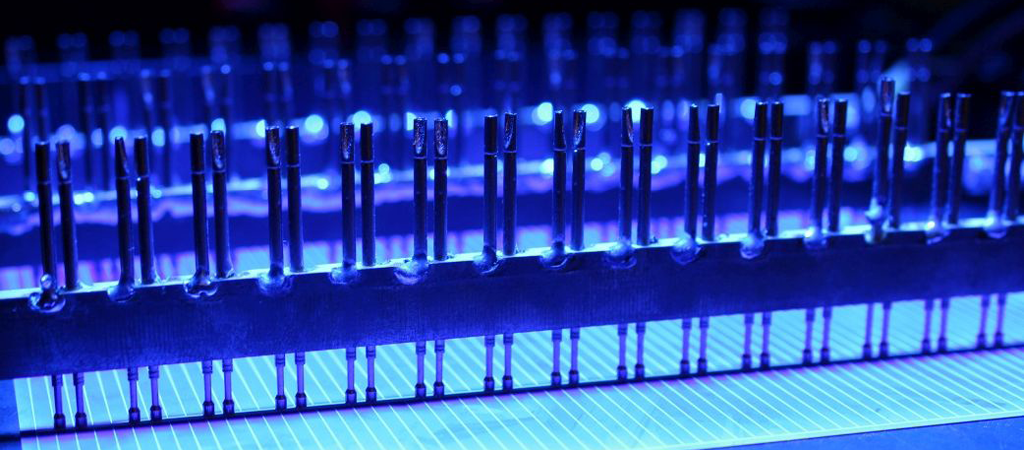

Fraunhofer CSP operates a fully integrated measurement and classification cluster for the analysis of solar cells and wafers at their location in Halle. This platform provides the basis for carrying out comprehensive measurement methods flexibly in a fully automated analysis cluster so that all resulting data can be recorded according to individual components (solar cell or wafer). Automatic loading and unloading is just as much part of the configuration as the marking system and laser-assisted treatment and measurement.

The FabEagle®MES from Kontron AIS was installed as a central data collection and evaluation platform. The virtual tracking functionality of the FabEagle®MES enables data from loading through the three process steps (marking, laser treatment, measurement) to unloading to be assigned to the respective materials on an individual component basis. This enables cross-process data correlations, evaluations and analyses.

Processed material is packaged in clearly identifiable batches that are provided with unique identification labels so that the data can later be matched with the physical material.

“The MES from Kontron AIS offers us high flexibility and the range of functions that we need to analyze data within the framework of customer orders and research projects.”

Dr. Marko Turek, Team Leader at the Fraunhofer Center for silicon photovoltaics CSP

Challenge

Challenge

- Proprietary machine interfaces

- No end-to-end material tracking concept, as there are no identification systems for material containers

Solution

Solution

- Introduction of a virtual material tracking concept based on movement and position signals from the individual devices

- Introduction of a flexible integration layer for the implementation of proprietary interfaces (API)

Result

Result

- Fully integrated system with maximum traceability based on FabEagle®MES

- Reduction or avoidance of manual data processing through integration of all system components

Basis for research and further expansion

The basic configuration for the research project was created quickly and efficiently using the current range of functions of the FabEagle®MES. The modular configuration of the Fraunhofer CSP platform with its processing and measurement systems makes it possible to extend the control and data transfer of the individual systems at any time, as well as integrate additional stations into FabEagle®MES.

The evaluations that are included as standard automatically take into account additional available data, without the platform operator needing to perform additional adaptation or implementation work.

Goals and level of innovation of the solution in the research project

The first stage of the project is to research and develop new measurement methods and applications. In addition to developing individual, modern measurement applications, data evaluation also plays a central role. The Fraunhofer CSP wants to offer its customers the following capabilities with this research project:

- Provide new measurement methods and digitally linked measurement chains that allow improved production control that adds value compared to competitors.

- Enable equipment manufacturers and software developers to provide machine learning algorithms that were developed specifically for the respective measurement method and instructions for intelligent process control and control or a classification of defective solar cells with significantly increased reliability to reduce scrap and reduce investment.

- Achieve shorter cycle times when optimizing production processes based on new in-line measurement concepts to increase average cell efficiency.

- Detect production deviations at an early stage due to comprehensive, end-to-end automated data collection to reduce downtimes.