Imagine a factory where every machine not only does its job but is also part of a much larger network; a network that collects, analyzes, and makes decisions. Edge devices make this vision a reality. These small but powerful devices provide an essential bridge between on-site production machines and the world of cloud-based analytics and data processing. This opens up new potential for component and device manufacturers as well as equipment manufacturing firms to design their products more intelligently and at the same time optimize their operating processes. Find out how modern IoT solutions can be developed from the edge to the cloud to not only increase performance but also ensure that systems are ready for future challenges.

What do security and connectivity have to do with fleet management and digital services?

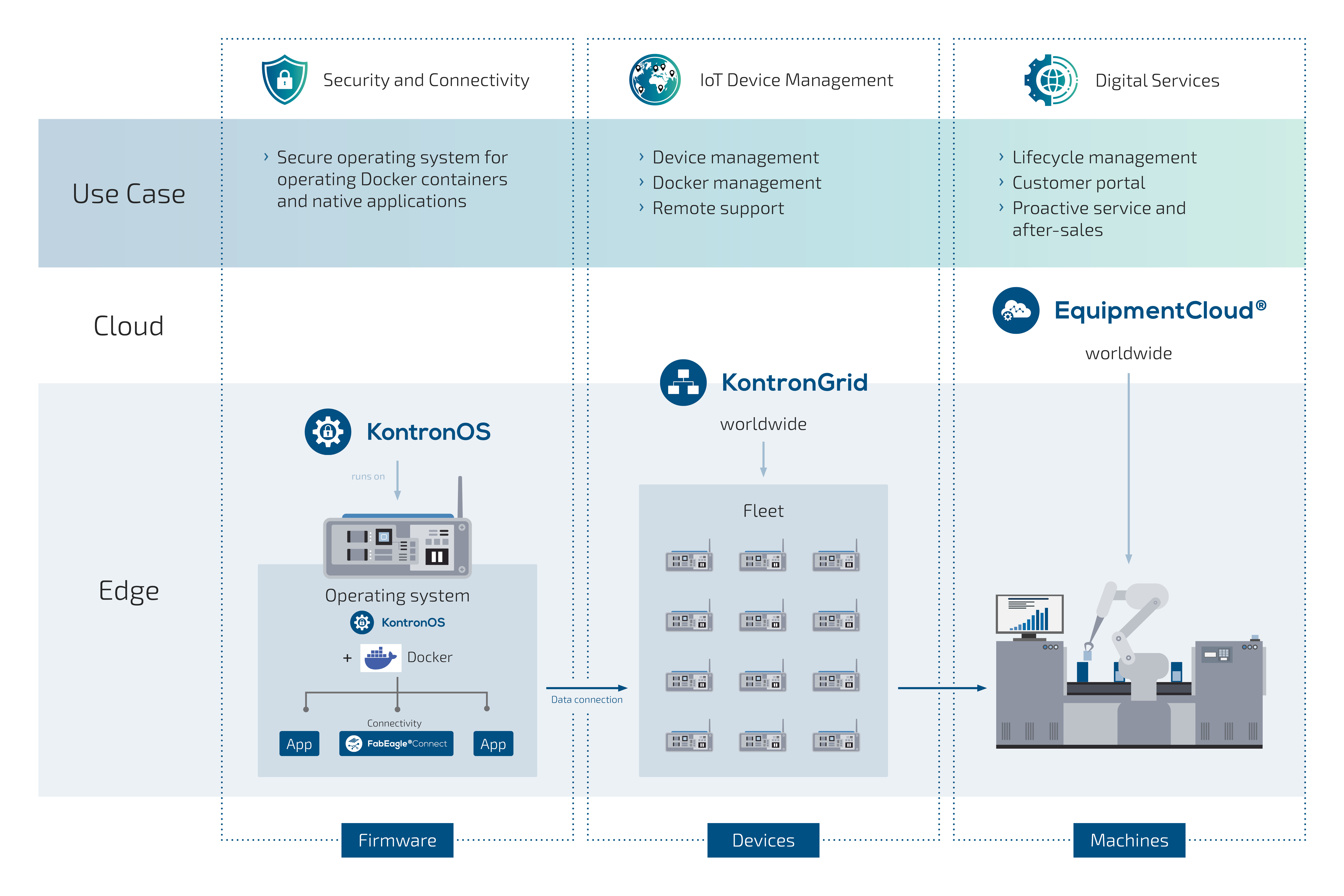

The best way to answer this question is to take a look at practical scenarios covered by Kontron AIS. Three software products from the susietec® toolkit portfolio play a central role here, that are not only seamlessly matched, but can also be used independently of each other in industrial automation and equipment manufacturing.

At the heart of IoT solutions are compact, high-performance edge devices, which are integrated into components, systems and machines all over the world. They serve as a data buffer and processing unit to run intelligent applications. Their areas of application are both diverse and complex. Component and device manufacturers as well as equipment manufacturing companies are keen to launch data-based IoT solutions to make their products more intelligent and future-proof and to provide the basis for increasing production volumes. A key differentiating feature of these products is the integrated software component. This is an area where component and device manufacturers have specialized and built up core competencies in order to differentiate themselves from the competition over the long term.

The connection between these applications is reflected in the high number, global distribution and access challenges while ensuring maximum uptime. The high security specifications for applications, which include both compliance with legal requirements and use in critical environments, make failures particularly critical.

So how can the challenges associated with security and operational risks be effectively solved?

Inadequately managed edge devices have serious vulnerabilities such as compromises, risk of external access, and uncontrolled updates. These vulnerabilities jeopardize the smooth and secure operation of customer-specific applications that are containerized or native, if the operating system is not secure.

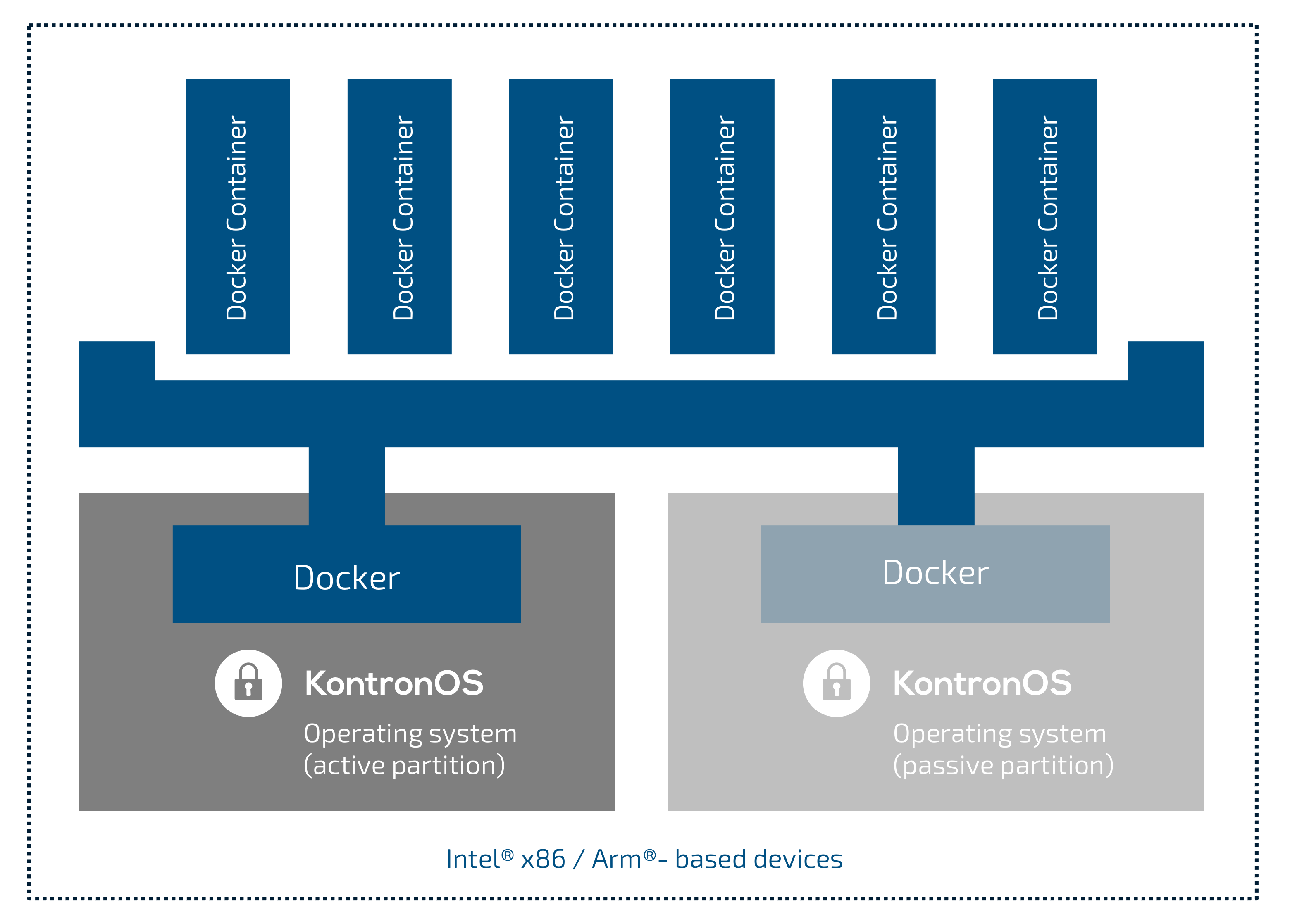

In order to effectively prevent this and ensure both security and stability, the answer to solving this problem lies in implementing hardened operating systems specifically for Linux-based edge devices. KontronOS gives component and device manufacturers a hardened operating system for reliable operation in edge devices over the entire product life cycle. The operating system is reduced to essential functions and is optimally tailored to the operation of Docker containers and use on a wide range of hardware.

The advantages of KontronOS at a glance:

Two active and passive partitions ensure maximum uptime in the event of an outage or a failed update. The system can automatically roll back to an older, stable version.

KontronOS offers a robust, high performance platform for containerized applications, which guarantees a secure operating environment on networked devices.

KontronOS was developed based on Yocto Linux and supports both Intel® x86 and ARM® based devices.

The operating system includes all necessary functions for efficient operation without unnecessary ballast.

Continuous assessments of common vulnerabilities and exposures (CVE) and common weakness enumeration (CWE) ensure high security standards.

A user-friendly interface allows you to configure network zones, integrated firewalls and IP addresses as well as backup and restore system configurations.

A strict separation between operating system and application level enables the independent use of Docker containers.

Support for boot level security mechanisms, including TPM 2.0 for x86 and high assurance boot (HAB) for ARM® devices, increases boot process integrity.

In addition to a secure operating system, connectivity plays an important role as a further component for IoT solutions. Especially when it comes to integration projects to connect devices and machines, it is an advantage to be able to use common data interfaces, with the focus on configuration and not on programming. The FabEagle®Connect interface integration solution, which is pre-installed as a Docker container on edge devices, enables functioning interface configurations for connectivity to be created after just a few minutes of training thanks to reusable components and guided configuration dialogs. This allows data from production to be transferred to IoT applications via cloud interfaces such as REST, MQTT and ActiveMQ, or to use proven IT interfaces such as OPC UA, TCP/IP, Modbus and RS232 as a standard for connecting machines and devices.

How can IoT solutions be scaled efficiently worldwide without having to acquire complex know-how?

What is needed is a comprehensive fleet management solution for edge devices that can be used to manage thousands of device connections worldwide at a glance. For IT managers, the challenge is to minimize complexity for IT teams and free up IT resources while ensuring 24/7 control over the globally distributed fleet of devices at the same time as meeting the highest security standards and compliance requirements. Software architects responsible for developing containerized applications and therefore the core of the IoT solution want to ensure secure data exchange using comprehensive end-to-end encryption mechanisms, expect continuous deployment during operation, and make it as easy as possible to create and manage containers for scalable applications. For service and support staff, the focus is on cost efficiency, minimizing travel costs, efficient troubleshooting, high quality support and proactive action when it comes to the long-term operation of IoT solutions.

To meet these high requirements, an advanced fleet management solution is required that not only simplifies global monitoring of the device fleet, but also allows container-based applications to be rolled out without manual effort. This is supported by configurable image templates, which make it easy to test and roll out update scenarios on globally distributed edge devices. If service support is required, quick and efficient remote access must be possible not only to the edge device, but also to the PLC level of the connected machine or system.

The IoT device management solution KontronGrid combines all these functionalities in one solution by providing five integrated services to offer component, device and equipment manufacturers the following advantages:

Meets all IoT requirements due to seamless integration of software and hardware, which enables rapid implementation and high cost efficiency

Ready for immediate use without hidden costs or additional development effort, based on a tried and tested and fast onboarding process.

Minimizes the effort required to comply with the ISO 27001 standard and offers simplified access to IEC 62443 certifications for IoT projects at the highest level of security.

Provides the necessary infrastructure to make managing the device fleet easier so that the development team can focus on application development.

Grows with the size and variety of applications and is scalable down to machine level.

How can customer loyalty be sustainably optimized and digital services launched as a new business model over the entire life cycle of a machine?

Digitalization in equipment manufacturing is not a trend, but a strategic necessity for remaining competitive in today's fast-moving and technology-driven world. Large companies have already taken this path and have shown that digital transformation is feasible and profitable. SMEs are also increasingly faced with the potential and urgency to digitalize their business models to ensure long-term growth.

Digitalization efforts are accompanied by a strategic change process that examines existing procedures and processes, rethinks customer communication, and exposes data gaps, breaches and silos. Not only does that sound complex and time-consuming, it really is. Companies that have embarked on this path discovered this fact early on and made resources, freedom and budgets available to all their digitalization teams. All the same, it is best not to remain completely in the dark on this kind of project, and better to rely on practical and industry-related experience that has already been successful, instead of going it alone.

Equipment manufacturing companies combine digitalization effort so that service and after-sales can be successfully transformed and evolve from a cost center to a profit center. As a result, the company becomes future-proof. Management then has the challenge of proving sustainable success. Due to the increasing shortage and increased turnover of skilled workers, they need to be employed in a way that maximizes their full potential to increase the competitiveness of the company. In addition, customer loyalty can be improved by services and touchpoints along the entire machine life cycle. In order to achieve this objective, the machines and components must be continuously monitored so that remote maintenance can be carried out at any time. Service, after-sales and support are faced with the challenge of actively expanding their service business.

The digital customer portal EquipmentCloud® offers an ideal platform for this. With nine configurable and interactive modules, it helps companies implement and manage digital services over the entire life cycle of a machine. Features include:

Creates a central interface for interaction between manufacturers and operators, enabling seamless communication and collaboration.

Enables efficient monitoring and analysis of globally distributed machine fleets, so there is a quick response to potential problems.

Provides plannable and traceable processes that can be carried out and documented on the go to increase operational efficiency and reduce downtime.

Processes and transmits data securely from machine level to the cloud, allowing new business models to be implemented based on data analysis and optimizations.

Equipment manufacturing companies get guided on-boarding and custom-built customer success management processes to make sure they successfully launch a digital service offering within three months. The efficiency of each employee is increased using individual dashboards, and communication with the customer can be carried out using the system in the customer’s language to create a customer experience with high recognition value that reflects the company’s corporate identity. Security is the most important factor when it comes to enabling data-driven services from the machine level to the cloud.

The prerequisite for launching digital services is the direct connection of the machines in order to create the necessary database. This is where the edge device, also known as an IoT gateway, plays a special role in buffering, preprocessing and transmitting the data from the machines and systems to the EquipmentCloud® in as near real time as possible. Connectivity is implemented by the pre-installed FabEagle® Connect container described above or, alternatively, by an agent also available as a container (node-red based).

While taking into consideration the overall system, with increasing scaling, EquipmentCloud® focuses in particular on the worldwide management of integrated IoT devices. After all, not every medium-sized equipment manufacturing company has local service branches that can access the devices within a very short time period. That is why remote access and easy monitoring of edge devices are essential. For this reason, KontronGrid functionality has been implemented as an optional module within EquipmentCloud®. The two products therefore complement each other on this level as well.