FabEagle®MES für PV-Zellfertigungslinie in den USA

Suniva hat seinen Hauptsitz in Norcross (Georgia, USA) und ist der älteste sowie größte Hersteller monokristalliner Solarzellen in Nordamerika.

Seit 2007 nutzt Suniva in den USA entwickeltes geistiges Eigentum, um mehrere Generationen von Zelltechnologien einzuführen – jede neue Generation zeichnet sich durch höhere Wirkungsgrade und geringere Produktionskosten aus.

Die Zellfertigungsprozesse erreichen dabei durchgängig Kosten auf dem Niveau globaler Wettbewerber. Seit 2010 ist Kontron AIS verlässlicher Partner für MES-Systeme und maßgeschneiderte Softwarelösungen, um alle relevanten Prozessdaten zu erfassen, zu visualisieren und die Produktion zu steuern.

Im Jahr 2024 begann Suniva mit dem Bau einer neu gestalteten Solarzellenfertigung, deren erste Ausbaustufe eine Jahreskapazität von 1 GW umfasst. Zusätzliche Erweiterungen sollen die Kapazität bis auf 2,5 GW steigern.

Die zentrale Herausforderung bestand darin, die hochmoderne PERC-Zellfertigungslinie in das MES zu integrieren, einschließlich virtuellem Einzelwafer-Tracking, und die Anlagenlieferanten aus Europa, Asien und den USA zu koordinieren.

Einige Zulieferer verfügten bereits über Erfahrung mit der Integration von FabEagle®MES, während andere einen abgestimmten Prozess durchliefen, um Schnittstellen für die Verfolgung der Material- und Anlagenleistung zu realisieren. Parallel dazu erfolgte die nahtlose Anbindung an das bestehende ERP-System innerhalb eines engen Zeitrahmens.

Herausforderung

Herausforderung

- Geringe Vorlaufzeit bis zum Produktionsstart (SOP)

- Erfassung von Daten auf Einzelwafer-Ebene zur Qualitätsoptimierung

- Integration von Anlagen mit hohem Durchsatz

Lösung

Lösung

- Starker Projektmanagement-Fokus durch das erfahrene Kontron-Team

- Implementierung eines virtuellen Single-Wafer-Trackings

- Enge Zusammenarbeit mit Anlagenlieferanten

Ergebnis

Ergebnis

- Termingerechte Lieferung mit übertroffenen Erwartungen

- Einzelzell-Tracking zur Unterstützung und Optimierung des Hochlaufs

- Zuverlässige MES-Schnittstellen mit hoher Performance über SECS/GEM, OPC UA und TCP/IP-XML

Das sagt Hawazin Abdullah von Suniva über die Zusammenarbeit

“Selbst in einem engen Zeitplan hat Kontron AIS nicht nur termingerecht geliefert, sondern auch unsere Erwartungen übertroffen. Bei Suniva sagen wir oft, dass Kontron AIS unser Lieblingslieferant ist – ein Gefühl, das ihren hervorragenden Service und ihr Engagement widerspiegelt.”

Hawazin Abdullah, MES Implementation Manager, Suniva Inc.

Suniva und Kontron AIS arbeiten gemeinsam am Aufbau einer neuen Produktionslinie

Das Projekt brachte einige Herausforderungen mit sich, insbesondere bei der Einrichtung der neuen Gigawatt- Photovoltaik-Zellproduktionslinie und der Koordination etablierter sowie neuer Lieferanten. Die Verwaltung dieser unterschiedlichen Lieferantenbeziehungen erhöhte die Komplexität, vor allem, weil die Lieferanten über Nordamerika, Asien und Europa verteilt sind, daher in verschiedenen Zeitzonen agieren und sowohl Anlagen als auch Software liefern. Dank sorgfältiger Planung und effektiver Kommunikation im gesamten Team konnten wir diese Komplexität erfolgreich auflösen und eine reibungslose Integration sicherstellen.

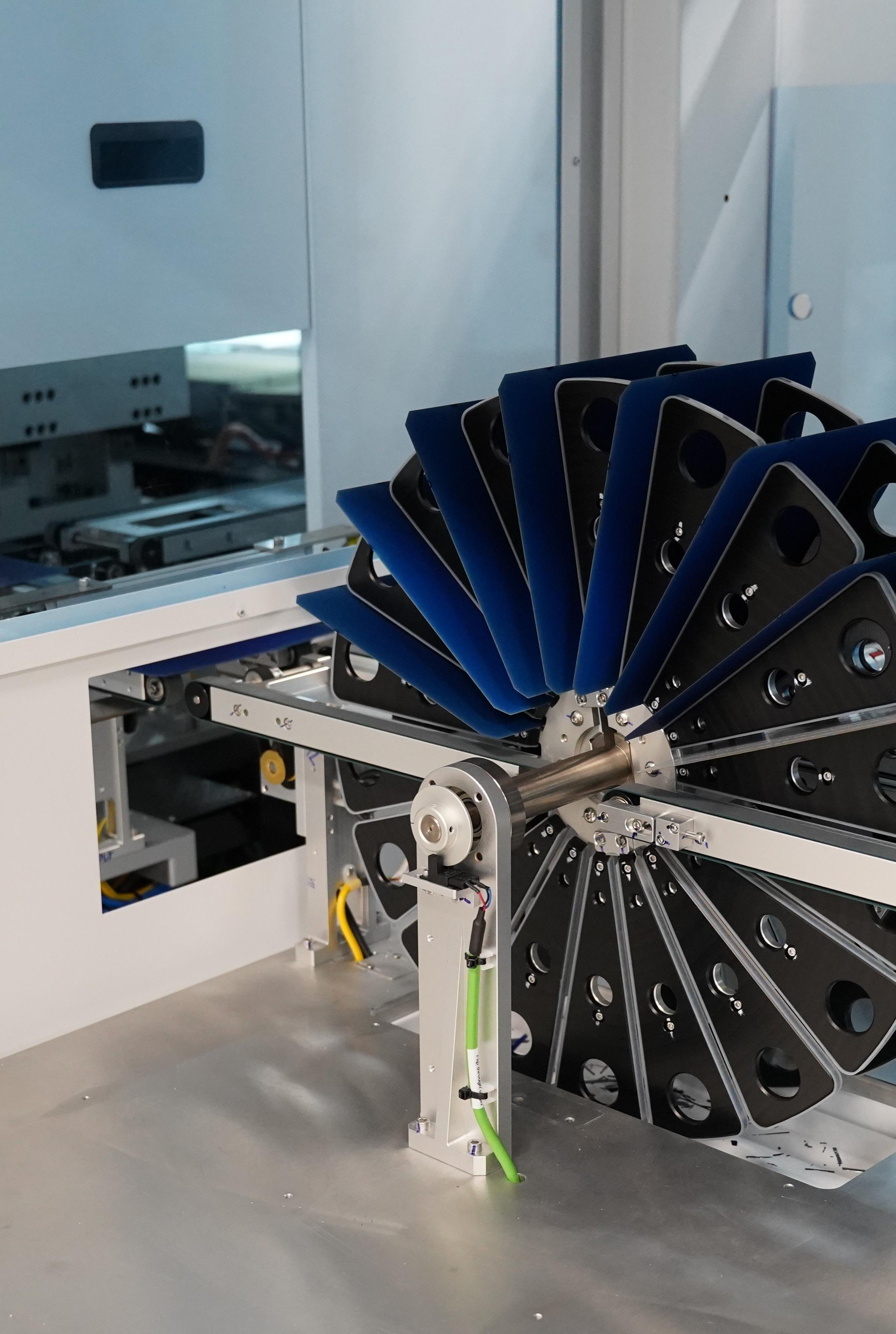

Die neue Produktionslinie ist auf hohen Durchsatz ausgelegt und nutzt optimierte Pufferkonzepte in der Automatisierung sowie Hochvolumen- Verarbeitungsanlagen. Eine weitere Herausforderung: Der Zeitrahmen war knapp, mit nur kurzer Vorlaufzeit bis zum Produktionsstart.

Planung für den Erfolg

Um das Ziel eines schnellen Hochlaufs der Fabrik zu erreichen, war eine detaillierte Planung unerlässlich. Die Erfahrung aus dem zuvor abgeschlossenen MES-Projekt sowie die Expertise von Suniva trugen dazu bei, ein gemeinsames Verständnis der für ein erfolgreiches Projekt erforderlichen Schritte zu schaffen. In Vor-Ort-Workshops wurden detaillierte Spezifikationen erstellt, die den gesamten Prozess abdecken – von der Wafer-Kommissionierung bis zur Verpackung der klassifizierten Solarzellen.

Dies umfasste die Definition eines Konzepts für das Einzelwafer-Tracking, um die Qualität sicherzustellen und Prozesse für die Massenproduktion weiter zu optimieren. Die Anforderungen an das Tracking der Anlagenleistung wurden ebenfalls definiert, um als Basis für Echtzeit- KPI-Berechnungen und -Trends, etwa der Gesamtanlageneffektivität (OEE), zu dienen. Zusätzliche Workshops mit jedem Anlagenlieferanten – wahlweise per Web-Meeting oder vor Ort – dienten dazu, die Anforderungen festzulegen und das Design der Schnittstellen zum MES abzustimmen.

Integrationsschicht für Anlagen

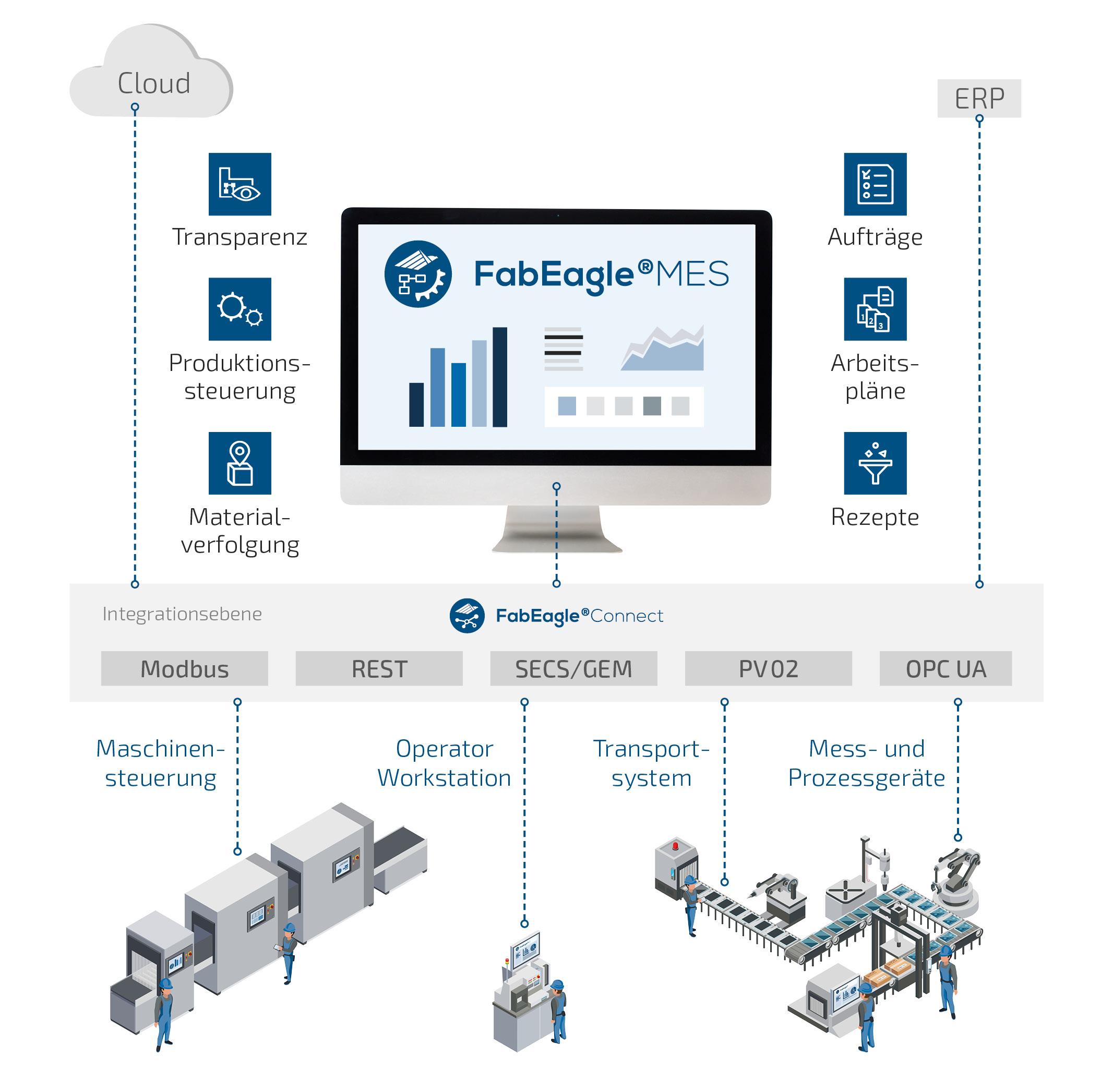

Das Projekt umfasste die Integration verschiedener Anlagenschnittstellen, je nach Performance-Anforderungen und Verfügbarkeit beim Anlagenlieferanten. Dies beinhaltete Industriestandards wie SECS/GEM und OPC UA sowie herstellerspezifische TCP/IP-XML- oder Datenbankschnittstellen. Um die Zuverlässigkeit und den Funktionsumfang sicherzustellen, wurde für jeden Lieferanten eine spezifische Spezifikation erstellt, mit der die Anforderungen für das Tracking von Material- und Anlagenleistung klar definiert wurden. Insgesamt umfasste dieses Projekt über 150 einzelne Prozessanlagen und Messgeräte in mehr als zehn Prozessschritten.

Da Kontron in Asien Support bereitstellt, waren lokale Softwareexperten Teil des MES-Teams, um Sprachbarrieren zu reduzieren und eine reibungslose Kommunikation mit allen asiatischen Lieferanten zu gewährleisten.

MES-Rollout vom Shopfloor bis zum Topfloor

Bei Suniva wurde die neueste MES-Version von Kontron AIS implementiert und mit einer umfassenden Web-Oberfläche ausgestattet, die den Operator Workstations auf dem Shopfloor die Produktionssteuerung ermöglicht. Das MES unterstützt zudem Office Workstations für die Konfiguration von Workflows und die Analyse der erfassten Produktionsdaten. Die Datenanalyse erfolgt über ein speziell auf die Solarzellenproduktion ausgerichtetes Berichtssystem, das Standardstatistiken wie Heatmap-Visualisierungen und Korrelationen liefert.

Zur Überwachung der Gesamtproduktion kann eine konfigurierbare statistische Prozesskontrolle (SPC, Statistical Process Control) eingesetzt werden. Der Produktionsablauf wird vollständig von FabEagle®MES gesteuert – von der Kommissionierung der Rohwafer an spezialisierten Operator Workstations über das Klassifizieren und Sortieren der Solarzellen bis hin zum Drucken von Etiketten für die mehrstufige Verpackung in Boxen.

Auch hierfür wurden Operator Workstations für die Verpackung eingerichtet. So konnte eine lückenlose ERP-Integration für die Nachverfolgung von Wafer-Verbrauchsmaterialien und Zellleistung umgesetzt werden.

MES benötigt eine IT-Infrastruktur

Die Skalierbarkeit des MES-Systems bereitet Suniva auf die künftige Fabrikerweiterung mit noch höherer Kapazität vor. Dies wird erreicht, indem die hohe MES-Last auf verschiedene MES-Dienste verteilt wird, um einen effizienten und zuverlässigen Betrieb sicherzustellen. Die Sicherheit der wertvollen Daten wird durch Datenbankkonzepte wie Datenbankpartitionierung und Replikation sichergestellt. So lassen sich hochvolumige Produktionsdaten im Terabyte-Bereich verarbeiten – eine zwingende Voraussetzung für schnelle Berichterstellung und Echtzeit-Prozessüberwachung.

Die IT-Infrastruktur wird vollständig vom IT-Team von Suniva organisiert, wodurch fortlaufender Support und Datensicherheit für die MES-Applikation und die Datenbankserver sichergestellt sind.

Nahtlose Integration von FabEagle®MES in Sunivas Zellproduktionslinie

Suniva und Kontron AIS haben eine weitere Zellproduktionslinie eingerichtet. Die MES-Lösung wurde termingerecht und im Budget geliefert. Die Flexibilität von Kontron AIS bei der Anpassung an Sunivas Anforderungen sowie die Ermöglichung einer nahtlosen Zusammenarbeit mit allen relevanten Zulieferern waren entscheidend für die robuste Integration von FabEagle®MES in die vorhandene IT-Infrastruktur.

FabEagle®MES steuert die Produktion und erfasst automatisch alle relevanten Anlagen-, Material- und prozessbezogenen Daten für jeden Produktionsschritt. Sämtliches Material wird auf Einzelwafer-Basis entlang der gesamten Produktionslinie nachverfolgt, wodurch Daten über mehrere Prozessschritte korreliert werden können. Dies ermöglicht Ingenieurinnen und Ingenieuren, Prozessabhängigkeiten zu analysieren und Fehlerursachen bei Qualitätsproblemen zu identifizieren.

So lassen sich Prozessstabilität überwachen und alle erforderlichen Daten bereitstellen, um die Zellqualität weiter zu optimieren. Mit der Abdeckung des kompletten Prozessablaufs – von der Kommissionierung der Rohwafer über das Klassifizieren und Sortieren der Solarzellen bis hin zur Verpackung – unterstützt das MES außerdem die vollständige Integration in das ERP-System. FabEagle®MES realisiert eine Softwarelösung, die alle Kundenanforderungen erfüllt und Transparenz, Rückverfolgbarkeit sowie Produktionskontrolle in einer Hochvolumen-Gigawatt-Zellproduktionslinie sicherstellt.